Introduction

For hospitality, multifamily amenities, HOAs, and commercial patio programs, finishing isn’t cosmetic-it’s lifecycle economics. Patio Furniture Powder Coating (pretreatment + electrostatic powder + thermal cure) reliably delivers film build, color retention, and corrosion resistance on aluminum/steel frames, while sprays (aerosol or liquid) shine for small runs, mixed materials, and field touch-ups.

This spec-ready guide compares both options with references to AAMA/FGIA architectural standards, QUALICOAT, ISO 9227 salt spray, and the EPA’s 2025 aerosol VOC amendments so you can defend choices in RFQs. See: AAMA 2604-22 store page, AAMA 2605 overview, QUALICOAT Specifications 2024, ISO 9227:2022 summary, and the EPA’s 2025 aerosol coatings fact sheet (PDF) / final rule in the Federal Register. [For more information, please read: Outdoor Furniture Frame Metals-Aluminum vs. Steel]

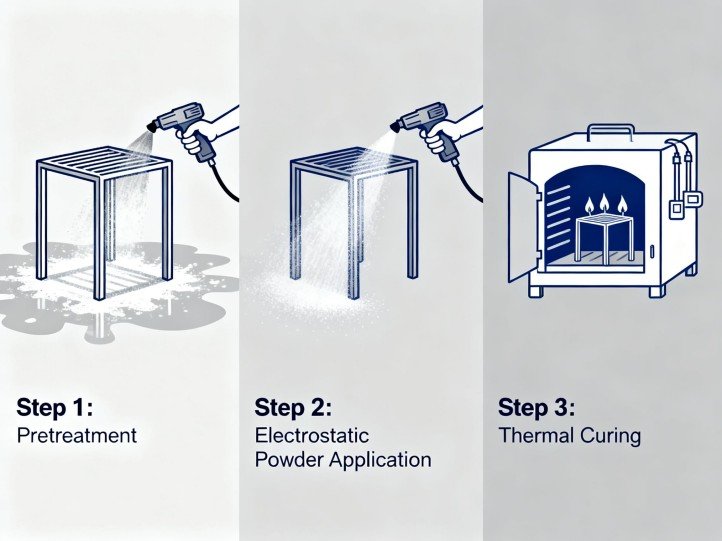

What “Patio Furniture Powder Coating” Actually Means

Process. Powder is electrostatically applied to a conductive frame, then baked so the film melts, flows, and crosslinks. Cure must be controlled by part metal temperature (PMT), not just “time in oven.” Polyester powders commonly specify ~400 °F / 204 °C for ~10 minutes at PMT (always follow supplier TDS). See: PPG: What is a cure curve? (PDF) and IFS Cure Charts (PDF). (KC User Content)

Typical film build. Architectural outdoor powders typically run ≈50-100 µm (2-4 mils) DFT; appropriate build is central to chip/corrosion resistance and warranty claims. See process notes and DFT ranges in: IFS Cure Charts and IFS technical guides.

Pretreatment & substrates. Multi-stage cleaning + conversion coatings (e.g., phosphate systems) underpin adhesion and corrosion resistance for aluminum/steel. Primer layers may be specified for steel or aggressive sites. See primers/pretreatment primers: Powder coating pretreatment guide (Tiger) and Practical application of phosphate pretreatment (PDF). Why powder at all? Powder coatings are typically solvent-free (negligible VOCs) and support overspray reclamation, which improves EHS and cost control.

What Counts as “Sprays” and When They Fit

Use cases. Sprays (aerosol or conventional liquid) excel for small batches, mixed materials (e.g., powder-coated frames with non-ovenable wicker/resin details), color trials, and field touch-ups. Consumer aerosols like Rust-Oleum Painter’s Touch 2X Ultra Cover list coverage on metal, most plastics, wicker, and more; see also the 2X TDS (Canada). For technique basics, Better Homes & Gardens’ guide covers distance, overlap, and light-coat timing: Spray paint tips. (Rust-Oleum) Compliance & safety. U.S. aerosol sprays fall under the EPA National VOC Emission Standards for Aerosol Coatings. The EPA finalized amendments on Jan 6, 2025, with rule text published Jan 17, 2025; align internal refurb SOPs accordingly. See the EPA’s fact sheet (PDF) and final rule.

Standards You Can Name in Specs

FGIA/AAMA 260x. Many patio buyers borrow fenestration-grade categories for aluminum frames:

- AAMA 2603 – Good performance (shorter exterior).

- AAMA 2604 – High performance, typical ~5-year South Florida exposure requirement; tighter ΔE/chalk/gloss limits.

- AAMA 2605 – Superior performance, ~10-year South Florida requirement; often liquid PVDF, but hyper-durable powders exist to target 2605. References: FGIA AAMA 2604-22; AAMA 2605 overview.

QUALICOAT. Global architectural spec controlling processes/tests; owners may require QUALICOAT-approved applicators and specific Class performance. See: QUALICOAT Specifications 2024 (official master). (QUALICOAT) ISO 9227 salt spray. Useful for comparative QC of pretreatment + coating stacks (especially near pools/coasts), but not a direct predictor of years in service; pair with AAMA/real exposure. See: ISO 9227:2022 summary.

Powder vs. Sprays – Decision Matrix

| Attribute | Powder Coating | Sprays (Aerosol/Liquid) |

|---|---|---|

| Typical film build | ≈50-100 µm (2-4 mils) in one bake | Thinner per pass; multiple coats to approach coverage |

| Cure | Thermal; e.g., PMT 204 °C/400 °F × ~10 min for many polyesters | Air/forced dry; no oven (ideal on-site) |

| Durability & weathering | Can be specified to AAMA 2604/2605 levels with the right chemistry/process | Product- and prep-dependent; generally lower outdoor class |

| Corrosion resistance | Strong with pretreatment + DFT control; verify with ISO 9227 + AAMA exposure | Variable; light builds/on-site conditions can limit corrosion performance |

| VOC/EHS | Typically solvent-free; overspray reclaim | Governed by EPA Aerosol Coatings VOC; higher VOCs are typical |

| Throughput | Excellent for batch/line; consistent QA | Best for small runs & touch-ups |

| Substrates | Conductive & ovenable (aluminum/steel) | Metal, wood, wicker, plastics-non-ovenable parts |

| Finish variety | Wide architectural palettes & textures (e.g., Interpon D2525 Structura) | Very wide consumer color availability |

| Typical role | Primary factory finish for frames | Refurb/touch-ups/mixed-material accents |

Sources: PPG-Advantages of Powder Coatings; FGIA/AAMA; QUALICOAT 2024; ISO 9227; EPA aerosol rule 2025; Interpon D2525 Structura (color card PDF).

Use-Case Playbook (What to Specify, Where)

Beachfront & Pool Decks (salt/chlorine, high UV).

- Aluminum frames: Specify hyper-durable powder targeting AAMA 2605 performance or PVDF liquid alternatives; require accredited pretreatment, DFT logs, and cure records. See: Interpon D3020 brochure-AAMA 2605 hyper-durable powder.

- Steel frames: Powder + robust conversion coat; add primer or duplex systems as needed.

- Non-ovenable wicker/resin parts: Use compatible sprays for color harmonization; follow label and VOC storage rules (EPA fact sheet).

Urban Rooftops/Sidewalk Cafés (abrasion, grime).

- AAMA 2604 super-durable polyester powder with low-gloss textures (e.g., Interpon D2525 Structura) to hide scuffs and reduce cleaning frequency. Vea: Interpon D2525 Struktura (EN color card). (Powder Coatings)

Shaded Courtyards & Semi-Outdoor Lounges.

- AAMA 2603/2604, depending on exposure window and budget; allow spray touch-ups in the operating manual. For training, embed pro videos from the Powder Coating Institute and Gema: PCI YouTube channel, Gema Switzerland.

[For more information, please read: Annual Outdoor Furniture Maintenance SOP Checklist]

Spec Language You Can Paste into an RFQ

Finish: Patio Furniture Powder Coating on aluminum frames, super-durable polyester meeting AAMA 2604-22 performance (or hyper-durable targeting AAMA 2605 for coastal/high-UV sites). Pretreatment: Multistage alkaline clean + chromate-free conversion per powder supplier recommendations. DFT: 2-4 mils (≈50-100 µm) measured per SSPC-PA 2; provide gauge logs. Cure: Per TDS (e.g., PMT 400 °F/204 °C × ≥10 min for standard polyester). Provide oven charts/cure records. Color/Sheen: Owner-approved RAL/architectural series; satin/texture preferred for abrasion and cleanability. QA: Adhesion, gloss, color, impact per supplier TDS; corrosion validation via ISO 9227 comparative panels; weathering per AAMA exposure class. Touch-Up: Provide matching spray product and on-site instructions for nicks/hardware. References: AAMA 2604-22 store page; ISO 9227 summary; PPG cure curve explainer (PDF); IFS Cure Charts (PDF).

Installation, Touch-Up & Warranty Notes

- Powder frames: Avoid post-delivery drilling/grinding. If unavoidable, deburr, spot-prep, and spray a matching touch-up. Keep a small lot of matching aerosols on site.

- Sprays on site: Train staff for light-coat technique, correct standoff, and overlap. For fundamentals, see BHG‘s spray paint tips. For process/warranty education, embed videos from PCI and Gema.

Conclusion

For metal patio frames where warranty, color retention, and corrosion resistance matter, specify Patio Furniture Powder Coating to an AAMA 2604 baseline (urban) or AAMA 2605 level (coastal/high-UV), with documented pretreatment, 2-4 mil DFT, and oven cure records. Reserve sprays for non-ovenable parts and field touch-ups. This split strategy maximizes lifecycle ROI and compliance (QUALICOAT/FGIA/ISO/EPA) while keeping onsite operations flexible. References: FGIA/AAMA, QUALICOAT 2024, ISO 9227, EPA aerosol rule 2025, PPG-Advantages of Powder Coatings.

FAQ (People-Also-Ask Style)

Q1: For coastal resorts, is Patio Furniture Powder Coating always better than sprays?

A: For metal frames, yes-spec a hyper-durable powder targeting AAMA 2605 performance (or PVDF liquid) with documented pretreatment, DFT, and cure records. Use sprays for non-ovenable parts and field touch-ups. See: AAMA 2605 overview and Interpon D3020 brochure.

Q2: What DFT should I ask vendors to hit?

A: 2-4 mils (≈50-100 µm) is typical for outdoor furniture powders; require SSPC-PA 2 measurement and oven charts in submittals. See: IFS Cure Charts (PDF) and SSPC-PA 2 (ANSI store).

Q3: Do aerosols run afoul of VOC limits?

A: They are regulated, not banned. The EPA finalized aerosol coatings VOC amendments in January 2025; align storage/usage with the final rule and any state overlays. See: EPA fact sheet and Federal Register rule.

Q4: Can I powder-coat resin/wicker parts?

A: No. Powder needs elevated bake temperatures, which deform most resins/wicker. Keep powder for metal frames; use compatible sprays on non-ovenable accents. See spray product scope: Rust-Oleum 2X Ultra Cover.

Q5: What should I write in RFQs for urban sidewalk cafés?

A: AAMA 2604 super-durable polyester powder (satin/texture) is a strong baseline; it balances cleanability and abrasion resistance. See: Interpon D2525 Structura (AAMA 2604-class brochure).