Why MOQ is a Profit Lever in Outdoor Furniture

Minimum Order Quantity (MOQ) determines whether your shipment hits material, setup, and logistics cost floors. In outdoor furniture wholesale—where items are bulky, seasonal, and material-intensive—an evidence-based MOQ improves landed cost, cash velocity, and container utilization.

Expert insight — Liu Chen, 15-year sourcing director across OEM/ODM outdoor furniture programs: “Teams that anchor MOQ in container utilization and EOQ math consistently negotiate 5–12% better unit economics than teams that only ‘push for lower MOQ’ without a model.”

Supplier Side: Why MOQs Exist (and Vary)

- Set-up/changeover costs: tooling swaps, powder-coat color changes, and fabric cutting setup.

- Upstream material MOQs: dye lots, foam block cuts, hardware carton packs.

You can learn about our products by material through this page: outdoor furniture materials & finishes (aluminum, rattan, teak, rope) - Packaging & master packs: carton sizes drive pallet patterns and master-carton counts.

- Capacity smoothing: factories use MOQ to balance line planning across peak/off-peak.

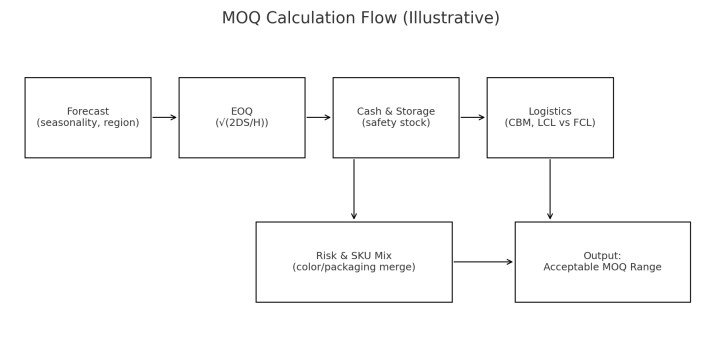

Buyer Side: A Step-by-Step MOQ Calculation

Start with demand forecasting

Build a rolling forecast by region/season. Separate project demand (hospitality roll-outs) from replenishment (distribution programs).

For Example:2025 outdoor seating trend guide (Adirondack)

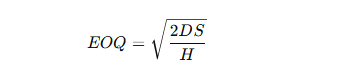

Use EOQ to find a cost-optimal anchor

Start with the classic EOQ formula:

- D = annual demand (units)

- S = ordering cost per PO (admin, inbound handling, brokerage per order)

- H = annual inventory carrying cost per unit

Good primers on the EOQ formula and assumptions: Investopedia — Economic Order Quantity (EOQ) and Corporate Finance Institute — EOQ. (Investopedia)

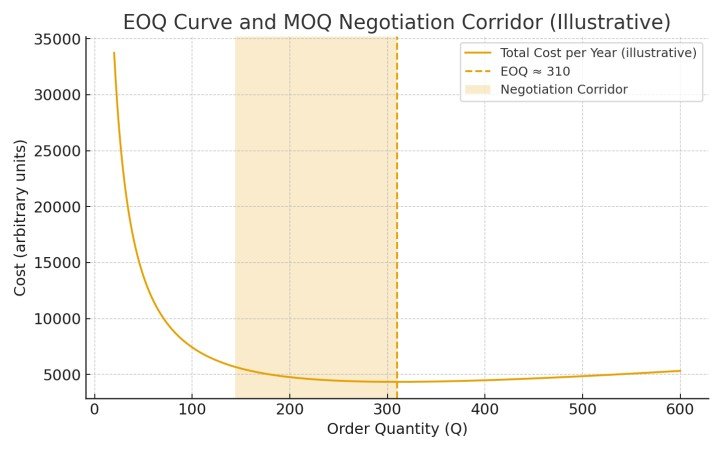

Note: EOQ ≠ MOQ. EOQ is buyer-optimal; MOQ is supplier-minimum. Use EOQ as your negotiation anchor before layering factory and logistics constraints.

Apply cash-flow and storage ceilings

Stress-test EOQ with budget caps, warehouse capacity, and lead time variability. Add safety stock policies for project risk.

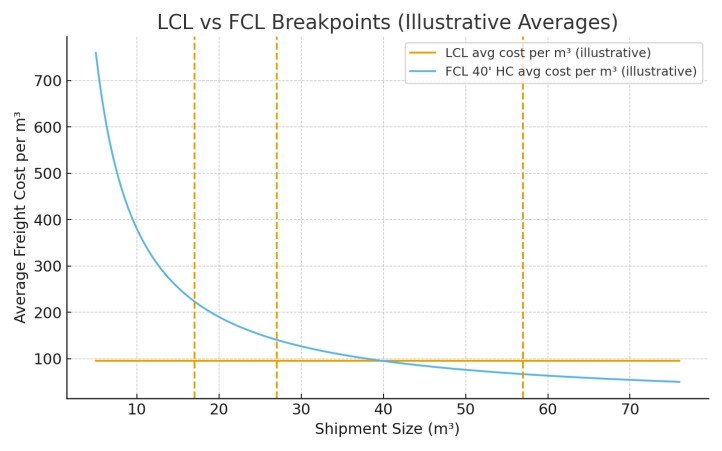

Check logistics breakpoints (LCL vs FCL)

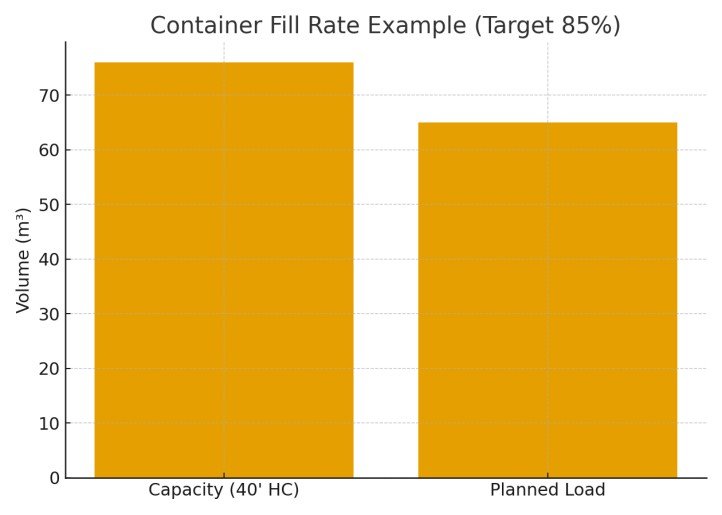

Translate SKU cube (CBM/carton × cartons) into container space. Representative internal volumes: ~67 m³ for a 40’ GP and ~76 m³ for a 40’ HC (Maersk equipment spec). (maersk.com)

A common quoting heuristic for when to switch from LCL to FCL used by forwarders:

- 20’ FCL if ≥ ~17 m³,

- 40’ FCL if > ~27 m³,

- 40’ HC FCL if > ~57 m³.

See Flexport Help: “Should I Select LCL or FCL?” for context; pair with a general Freightos LCL guide when modeling landed cost. (Flexport)

Output: an acceptable MOQ range

- Lower bound: cash-flow minimum that still satisfies safety stock.

- Upper bound: EOQ adjusted by container fill or storage constraints.

Negotiate within this corridor.

Worked Example (one SKU set)

| Input (example) | Value |

|---|---|

| Annual demand D | 2,400 sets |

| Ordering cost S | $280 per PO |

| Carrying cost H | $14 per set/year |

| EOQ | (\sqrt{2×2400×280/14} ≈ 276) sets |

| CBM per set | 0.45 m³ |

| 40’ HC target fill (85% of ~76 m³) | ~65 m³ usable |

| Container-anchored MOQ | (65 / 0.45 ≈ 144) sets |

| Negotiation corridor | 144–276 sets (refine with mix & cash) |

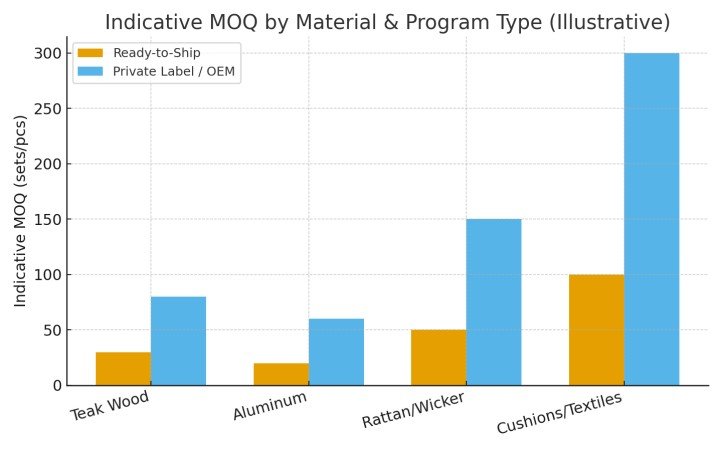

Material Benchmarks: Indicative MOQ Ranges (planning)

Ranges are illustrative for planning discussions with a teak outdoor furniture supplier, aluminum patio furniture wholesale partner, or rattan wicker outdoor furniture producer. Validate with current RFQs and seasonality.

| Material / Program | Ready-to-Ship (indicative) | Private Label / OEM (indicative) | Notes |

|---|---|---|---|

| Teak wood seating/table sets | 25–40 sets | 70–100 sets | Consider the FSC chain-of-custody for claims and RFQs. (fsc.org) |

| Aluminum powder-coat sets | 15–30 sets | 50–80 sets | Color batch & hang-line setup dominate. |

| Rattan/wicker over aluminum/steel | 40–60 sets | 120–180 sets | Weaving cells prefer longer runs. |

| Cushions & textiles (per color) | 80–120 pcs | 250–350 pcs | Fabric dye lots and foam block cuts drive MOQs. |

Ten Proven Ways to Reduce MOQ (without killing margin)

- Mixed container (multi-SKU, same material/finish) for master-pack and line efficiency.

(If you want to know more, you can read this article: Canopy Outdoor Sofa Use Cases for Hospitality Programs) - Color & packaging consolidation across SKUs to cut changeovers.

- Rolling forecasts with split deliveries (e.g., 60/40) tied to an annual volume.

- Off-peak production commitments in exchange for price/volume trade.

- Deposit tiers & price ladders linked to scheduled releases.

- Component standardization (shared frames, shared cushion cores).

- Leverage OEM/ODM outdoor furniture platforms—customize trims, not structures.

- Buyers’ consolidation to convert LCL to FCL where feasible.

- Master carton redesign to boost pallet and container utilization.

- Multi-buyer pooling across your distribution network.

Do Not Trade Quality & Compliance for Lower MOQ

- AQL sampling: adopt ANSI/ASQ Z1.4 with switching rules; align levels/defect classes. See ASQ — Z1.4/Z1.9 overview and QIMA’s ISO 2859-based AQL guide. (ASQ)

- Chemical & labeling: If distributing into the EU/UK, align with ECHA — Understanding REACH; for California distribution, reference OEHHA — Proposition 65. (echa.europa.eu)

- Sustainable timber claims: evaluate FSC chain of custody requirements for teak/acacia programs. (fsc.org)

- Corrosion/weathering: define finish performance (e.g., salt-spray hours for coated metals) and UV standards in tech packs.

- Pre-production (PP) approval: lock critical dimensions, weld integrity, and cushion fit before mass run.

Logistics Math: From CBM to a “Full-Container MOQ”

- Know your box: representative internal volumes—40’ GP ≈ 67 m³, 40’ HC ≈ 76 m³ (Maersk equipment specification). (maersk.com)

- Decide LCL vs FCL: use CBM breakpoints and local fee structures; Flexport’s LCL/FCL guidance provides helpful thresholds; combine with Freightos’ LCL guide for cost modeling. (Flexport)

Reference table (planning heuristic)

| Equipment | Internal volume (approx.) | Common “go-FCL” heuristic* |

|---|---|---|

| 20’ GP | ~33 m³ | ≥ ~17 m³ |

| 40’ GP | ~67 m³ | > ~27 m³ |

| 40’ HC | ~76 m³ | > ~57 m³ |

* Thresholds derived from Flexport quoting guidance; always model your all-in charges before finalizing. (Flexport)

- CBM calculator walkthrough (IncoDocs) — quick refresher for planners.

- Flexport webinar on container utilization — helpful for buyers’ consolidation ideas.

Case Snapshots (anonymized)

- Distributor Program (North America): adopting mixed-container releases cut average MOQ/SKU by 34% and lifted container fill from 71%→88%.

- Hospitality Project: EOQ-anchored negotiation + split deliveries redesigned a 220-set ask into a 140-set + 80-set plan at the same annual price, improving peak-season cash coverage.

- Dealer Network: moved to private label outdoor furniture with shared frames; MOQ held flat while line breadth tripled via trims and cushions.

Final Checklist Before You Commit to an MOQ

- EOQ math completed and validated against inventory carrying cost assumptions. See Investopedia — EOQ and CFI — EOQ formula for model framing. (Investopedia)

- CBM and LCL/FCL breakpoints modeled with current rate/fee assumptions. See Freightos LCL guide + Flexport thresholds. (Freightos)

- AQL plan, PP samples, and compliance clauses (REACH/Prop 65/FSC where applicable). (ASQ)

- Price ladder & release schedule captured in the PO.

FAQ (B2B quick answers)

Q1. What is a “reasonable” MOQ for outdoor furniture wholesale?

There is no single number—target a range anchored by EOQ and container fill. For planning, aluminum ready-to-ship sets can be feasible in the 15–30 range; private label often starts 50–80+, depending on finish and packaging.

Q2. MOQ vs EOQ—how are they different?

MOQ is a supplier’s minimum batch driven by cost/capacity; EOQ is your cost-optimal order size. Use EOQ first, then negotiate MOQ around logistics and cash constraints. See EOQ references above. (Investopedia)

Q3. How can we reduce MOQ without a price spike?

Consolidate colors/packaging, pursue mixed containers, commit to rolling releases, or shift to OEM/ODM outdoor furniture platforms with standardized structures.

Q4. Does private label raise MOQ?

Often yes—due to custom packaging, color batches, and unique components. Balance with shared platforms and split deliveries.

Q5. What quality controls are non-negotiable at low MOQ?

Maintain AQL Z1.4 inspections, PP approvals, and REACH/Prop 65 checks where applicable. (ASQ)

References (authoritative anchors)

- Investopedia — Economic Order Quantity (EOQ); CFI — EOQ formula (EOQ model & assumptions). (Investopedia)

- Maersk — Dry equipment specs (PDF) (40’ GP ≈ 67 m³; 40’ HC ≈ 76 m³). (maersk.com)

- Flexport Help — LCL vs FCL thresholds; Freightos — LCL guide (breakpoints & planning). (Flexport)

- ASQ — Z1.4/Z1.9 overview; QIMA — AQL guide based on ISO 2859 (inspection standards). (ASQ)

- ECHA — Understanding REACH; OEHHA — Proposition 65 (compliance). (echa.europa.eu)

- FSC — Chain of Custody (sustainable timber claims). (fsc.org)

- YouTube supplements: IncoDocs CBM walkthrough; Flexport container utilization webinar. (YouTube)