Introduction: Outdoor spaces that perform like your brand

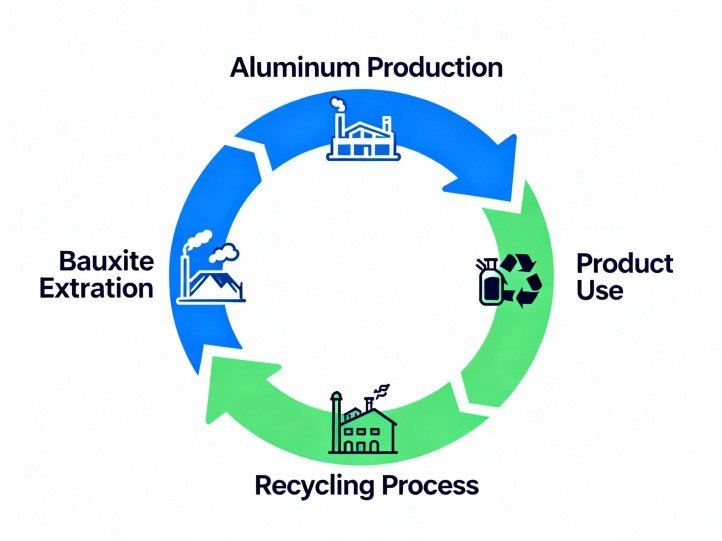

If you manage a hotel terrace, a resort pool deck, or a high-turnover restaurant patio, you already know the enemies: UV, salt air, chlorinated water, spilled cocktails, and thousands of guest-hours per week. “Buy nice or buy twice” applies brutally outdoors. High End Cast Aluminum Patio Furniture stands out because the base metal naturally resists corrosion and, when finished with the right architectural powder coat, keeps its color and gloss under punishing exposure-translating into fewer replacements, fewer service calls, and better lifetime ROI. Authoritative industry materials note that aluminum forms a protective oxide layer that helps resist corrosion in outdoor conditions (Aluminum Association). Sustainability is now a selection criterion for many hospitality brands. Almost 75% of all aluminum ever produced is still in use, and recycling aluminum saves around 95% of the energy required to make primary metal (International Aluminum Institute; IAI-Energy Savings). Those aren’t just nice talking points; they represent embedded value retention and credible ESG reporting.

Why cast aluminum excels outdoors

(1) Corrosion resistance + architectural coatings

Start with the substrate: aluminum forms a stable oxide skin that protects it from the kind of red rust that attacks ferrous metals. Add a high-performance architectural powder coat and you get a durable barrier against UV, humidity, and chemicals. In architecture, AAMA 2604 and AAMA 2605 are widely referenced performance tiers for exterior aluminum finishes, with increasing severity for accelerated humidity and salt-spray exposure and longer outdoor weathering benchmarks as you move up in class (FGIA overview blog). You’ll often see ASTM B117 neutral salt-spray referenced on spec sheets. It’s a widely used process-control test for pretreatment and coating lines, but by design, it does not directly predict years of outdoor life; ASTM itself cautions against using B117 results for real-world life prediction (ASTM B117 overview). Use it to compare process consistency across lots-not to extrapolate service years.

(2) Cast vs. extruded aluminum (use the right aluminum for the job)

“Aluminum” isn’t one thing. Cast aluminum is poured into molds, enabling intricate patterns, generous radii, and comfortable ergonomics in a single, solid component-great for classic dining chairs and chaise frames. Extruded aluminum is pushed through dies to create linear profiles (tubes, bars, channels) with excellent strength-to-weight, ideal for modern silhouettes and long spans in tables and lounges. Metallurgy references classify aluminum into casting alloys and wrought (extruded) alloys, each optimized for different fabrication routes and properties (ASM International-Subject Guide). Many premium collections combine both, leveraging cast components for sculptural comfort and extrusions for long, straight members.

The ROI story: a 10-year TCO you can defend

Below is an illustrative model for a 50-seat commercial patio (chairs only). Numbers are conservative placeholders to help you structure your RFP and vendor comparisons; adjust to your market and brand standards.

Table 1 – 10-Year TCO (Illustrative Model, 50 chairs)

| Material | Typical Unit Cost | Initial CapEx (50x) | Annual Care (Cleaning / Touch-ups) | Planned Refinish | Replacement Cycle | 10-Year TCO |

| High end cast aluminum (AAMA 2604-grade powder) | $350 | $17,500 | $1,000 | – | 12+ years | $27,500 |

| Powder-coated steel/wrought iron | $250 | $12,500 | $1,250 | $2,000 at Year 5 | ~7 years (swap at Y7) | $39,500 |

| Teak (commercial grade) | $450 | $22,500 | $1,500 (wash/seal) | – | 10-12 years | $37,500 |

Math check: Cast aluminum: $17,500 + $1,000×10 = $27,500. Steel/iron: $12,500 + $1,250×10 + $2,000 + $12,500 (Y7 replacement) = $39,500. Teak: $22,500 + $1,500×10 = $37,500. Why cast aluminum wins in this model

- Fewer failure modes: no red rust creep, fewer emergency pulls mid-season.

- Finish longevity: AAMA 2604-class powders are engineered for exterior UV and humidity resistance (FGIA overview).

- Sustainability dividend: high recycling value and strong circularity-~75% of aluminum remains in productive use; recycling uses ~5-10% of the energy of primary production (IAI recycling facts; IAI energy savings).

Sustainability and brand value

For multi-property owners, choosing durable, recyclable materials compounds over time. Aluminum’s circularity is unusually strong among structural metals-~75% still in use globally and ~95% energy savings when recycled, according to the International Aluminum Institute (see links above). Meanwhile, producers are scaling low-carbon aluminum through renewable power and process innovation; for example, Hydro recently announced a long-term supply of low-carbon aluminum wire rod for European grids, with emissions significantly below the global average (Reuters coverage). These trends strengthen the ESG story behind High End Cast Aluminum Patio Furniture-and can support procurement scorecards and sustainability reports.

Specification checklist (copy-paste into your RFP)

Coating & Pretreatment

- Exterior-grade powder with documented performance meeting AAMA 2604 or 2605 (or equivalent). Request current spec and date; for extreme UV/coastal sites, 2605-class performance is preferred (FGIA).

- Pretreatment appropriate to substrate and environment (e.g., multi-stage conversion coating, sealed; chromate-free options available). The Powder Coating Institute emphasizes substrate cleanliness, pretreatment quality, and cure control for adhesion and durability (PCI FAQ).

- Process evidence: provide salt-spray (ASTM B117) and humidity logs for current lots; acknowledge B117 as a comparative/process test-not a life predictor (ASTM B117 notice).

Frames & Castings

- Disclose casting alloy and wall thickness; specify acceptance criteria for porosity, surface finishing, and radius transitions.

- Provide foot glides (nylon/TPU) and protective pads to prevent coating abrasion on stone or pavers.

Hardware & Assembly

- Prefer 304/316 stainless or aluminum fasteners; avoid dissimilar-metal couples that can create galvanic corrosion in wet, salty environments; use isolating washers/sleeves where required (AMPP-Galvanic Corrosion basics).

Documentation

- Include finish warranty term and exclusions; for aluminum frames, note color/gloss retention benchmarks consistent with AAMA tier (supplier tech sheets from major finishers like Interpon/PPG map their systems to AAMA classes: Interpon overview | PPG AAMA collection).

[Read more: How to Specify 316L Stainless for Coastal & Poolside Resort Furniture]

Operations & care: SOPs that extend life

Daily/Weekly

- Rinse or wipe spills promptly; clean with pH-neutral detergent and soft cloths to avoid micro-abrasion of the powder film.

Monthly/Quarterly

- Inspect feet and contact points; replace worn glides to prevent finish wear-through.

- In coastal sites, schedule fresh-water rinses to remove salt deposits that can challenge any finish over time.

Seasonal/Annual

- Audit fasteners for tightness; apply light lubricant where specified.

- Use color-matched touch-up kits for edge nicks. Follow the finisher’s cleaning and scuffing protocol before applying.

For a quick primer on coating process fundamentals, this brief video from a global powder brand explains how powder coating is applied and why pretreatment/cure matters (“What is Powder Coating?” – Interpon/AkzoNobel). For technical maintenance and process FAQs, the Powder Coating Institute library is a reliable reference (PCI).

Comparison at a glance

| Attribute | Cast Aluminum | Powder-Coated Steel / Wrought Iron | Teak (Outdoor Grade) | Resin Wicker on Aluminum |

|---|---|---|---|---|

| Corrosion | Excellent (substrate + coating) | Fair-Good; risks at welds/chips | No rust; weathering/silvering | Excellent (aluminum frame + polymer shell) |

| Weight | Medium (wind-stable) | Medium-Heavy | Medium | Light |

| Finish options | Architectural powders (AAMA 2604/2605 performance achievable) | Architectural powders possible | Requires cleaning/sealing for color retention | Polymer + UV stabilizers |

| Typical lifecycle | 10-15+ years with care | 5-10 years (environment-dependent) | 10-12 years (higher care) | 5-8 years (weave quality dependent) |

| Maintenance | Low | Medium (rust touch-ups) | Medium-High | Medium |

Note: FGIA clarifies the increasing test severity and outdoor weathering expectations across AAMA 2603 → 2604 → 2605; use those classes to benchmark finish performance expectations for aluminum frames (FGIA blog summary).

Conclusion: Why High End Cast Aluminum Patio Furniture Wins

If your outdoor space is a profit center, the furniture must be durable, brand-correct, and predictable to maintain. High End Cast Aluminum Patio Furniture pairs an inherently corrosion-resistant substrate with proven architectural powder finishes to survive UV, salt, and scrutiny. It gives designers sculptural freedom, operates a low-touch maintenance plan, procurement a defensible 10-year TCO, and sustainability teams a credible circularity story backed by industry data. That combination is rare, and valuable (Aluminum Association-corrosion/oxide behavior; FGIA-AAMA classes; IAI-recycling facts).

FAQ (People Also Ask-friendly)

Q1: Is cast aluminum really better than tubular (extruded) aluminum for commercial patios?

A: They solve different problems. Cast aluminum offers sculptural shapes, integrated comfort, and stable weight that helps in windy locales. Extruded aluminum excels in long, straight members and lightweight modular frames. Many premium collections combine both, using cast for arms/legs and extrusions for rails and spans (ASM-cast vs. wrought classifications).

Q2: What coating spec should I require?

A: For year-round exterior use, specify powder finishes meeting AAMA 2604 (or 2605 for extreme UV/coastal). Ask vendors for test documentation and pretreatment details. Use ASTM B117 salt-spray data as process-control evidence, not a direct life predictor (FGIA blog summary; ASTM B117).

Q3: How long will High End Cast Aluminum Patio Furniture last?

A: With AAMA 2604-class powder, routine cleaning, and foot-glide upkeep, 10-15+ years is realistic in many commercial settings. Field life depends on environment and maintenance discipline; coastal properties should rinse frames more often and inspect hardware seasonally (see FGIA guidance on exterior performance tiers).

Q4: Is aluminum a sustainable choice?

A: Yes. ~75% of all aluminum ever produced remains in use, and recycling saves ~95% of the energy of primary production-strong numbers for ESG reporting and end-of-life planning (IAI-Recycling and Energy Savings; IAI-95% energy).

Q5: Does salt air ruin aluminum furniture?

A: Aluminum doesn’t red-rust like steel because of its oxide film, but chlorides can challenge any finish over time. The solution is the right pretreatment + AAMA 2604/2605-class powder and a simple freshwater rinse schedule in coastal environments (Aluminum Association-oxide behavior; FGIA-AAMA tiers).

References

-

- Aluminum Association: Water Staining & Oxide Layer Guidance – https://www.aluminum.org/sites/default/files/2021-11/WaterStainingGuidelines.pdf

- International Aluminum Institute: Recycling Facts – https://international-aluminium.org/work-areas/recycling/

- International Aluminum Institute: 95% Energy Savings – https://international-aluminium.org/landing/aluminium-recycling-saves-95-of-the-energy-needed-for-primary-aluminium-production/

- FGIA (formerly AAMA): Updated 2603/2604/2605 Context – https://fgiaonline.org/about/news-and-blogs/start-2023-with-the-most-recently-updated-fgia-standards-and-documents/

- ASTM B117: Neutral Salt-Spray Practice & Limitations – https://www.astm.org/b0117-19.html

- AMPP (NACE): Galvanic Corrosion Basics – https://www.ampp.org/technical-research/impact/corrosion-basics/group-1/galvanic-corrosion

- Powder Coating Institute: Process & Maintenance FAQs – https://www.powdercoating.org/?page=FAQ

- Reuters (2025-04-29): Hydro low-carbon aluminum supply deal – https://www.reuters.com/sustainability/climate-energy/hydro-signs-billion-euro-deal-supply-nkt-with-low-carbon-aluminium-eu-grid-2025-04-29/

- ASM International: Aluminum Alloys-Casting vs. Wrought – https://www.asminternational.org/aluminum-and-aluminum-alloys-subject-guide/