Introduction

In the outdoor furniture, marine seating, and hospitality sectors, material selection becomes a defining factor for product durability and performance. Traditional polyurethane foams tend to absorb moisture, slow drying, and eventual degradation under cyclical wetting and drying. Against this backdrop, high-density Quick Dry Foam has emerged as a premium solution to meet stringent functional demands. This article delves into the technical foundations, trade-offs, design guidelines, industry applications, testing protocols, and future outlooks for high-density Quick Dry Foam, aimed at material engineers, product specifiers, and sourcing professionals.

Fundamentals & Mechanisms

Definition and Structural Principles

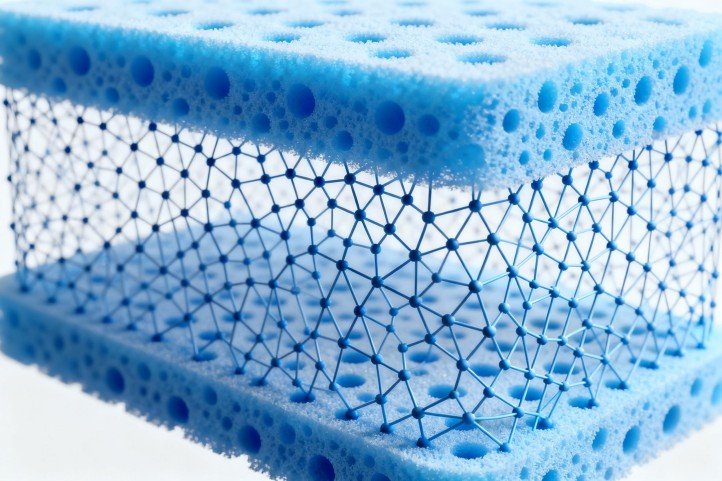

Quick Dry Foam, also known as reticulated or flow-through foam, is engineered via the removal of cell windows to yield a skeleton of open struts, allowing water to flow through freely. Unlike conventional closed-cell foams, which may trap moisture, reticulated foam exhibits a very open structure. (Wikipedia)

A prominent industrial variant, Urecel QuickDry, employs a Hydro-Blast Reticulation process to ensure > 90% open porosity. (Urecel Quickdry) The resulting network is optimized for both drainage and mechanical stability.

Because of its architecture, Quick Dry Foam enables rapid water evacuation and airflow circulation, critical in humid and outdoor settings. (eastar-group.com)

Density, Pore Architecture & Flow Path Design

While open porosity is essential for drainage, density is equally vital for mechanical stability. In “high-density Quick Dry Foam,” the objective is to maintain structural integrity (resistance to sagging, permanent set, creep) while preserving an interconnected pore network.

Key design variables include:

- Open porosity (void fraction)

- Strut thickness / skeletal cross-section

- Pore size distribution and connectivity (tortuosity)

- Channel straightness/path resistance

An optimal design ensures that under expected load, water pathways remain unobstructed and struts resist mechanical fatigue.

Drainage + Evaporation Mechanisms

The drying performance of Quick Dry Foam is realized through a coupled two-phase process:

- Bulk drainage (gravity + capillarity)

Water is channeled downward via internal conduits, ideally along nearly vertical, low-resistance paths. - Residual moisture evaporation

After the bulk water is evacuated, residual moisture adsorbed on struts diffuses outward and evaporates, aided by air exchange and convective airflow.

Ambient factors—such as temperature, relative humidity, and wind speed—significantly influence evaporation kinetics.

Trade-offs: Rapid Drying vs Comfort & Durability

Drying Speed vs Softness / Compliance

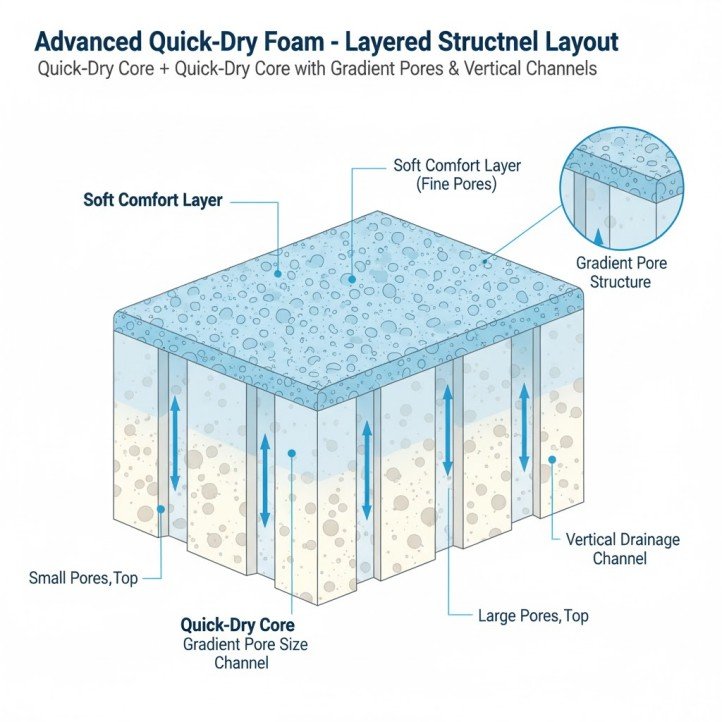

An excessively open structure improves drainage but may yield a firmer “hand.” To balance, many designs adopt composite or layered structures: a soft comfort layer over a high-density Quick Dry Foam core. This ensures an acceptable cushioning feel without compromising drainage.

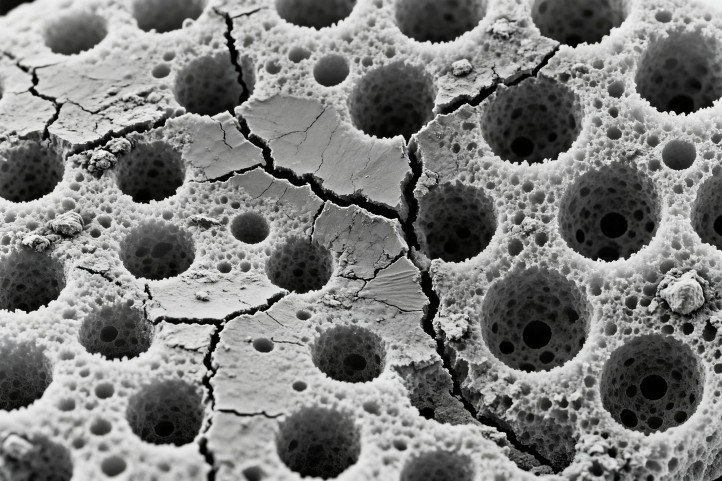

Durability & Aging vs Highly Open Structure

High openness means a greater exposed strut surface area, which is more vulnerable to UV, ozone, hydrolysis, and mechanical fatigue. Over time, struts may weaken, crack, or lose modulus. Research on open-cell foams shows that moisture ingress can alter viscoelastic characteristics. (arXiv)

Therefore, robust additive packages (UV stabilizers, antioxidants, antimicrobial agents) and protective measures are essential in long-term outdoor use.

Thermal / Insulation Considerations

Because of its high porosity, Quick Dry Foam generally has lower thermal insulation than closed-cell alternatives. In hot climates, this may aid cooling; in cooler settings, designers may need to supplement with insulating layers or hybrid composites.

Applications & Industry Case Examples

Outdoor Furniture & Resort Seating

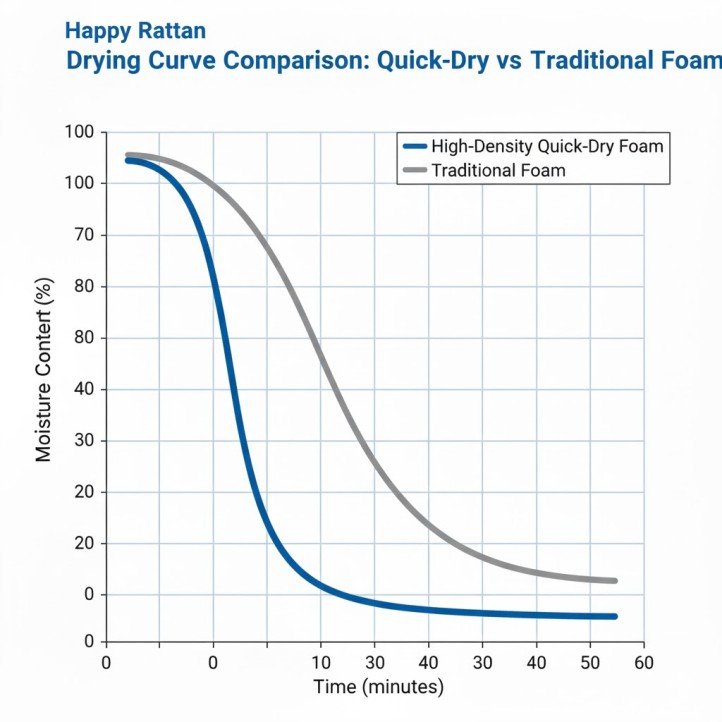

Premium outdoor lines increasingly incorporate high-density Quick Dry Foam in seating cores. Some reports claim full drying in 3 to 6 hours, compared to conventional foam cushions that remain damp for 24+ hours. (CG OUTDOOR FURNITURE)

Happy Rattan Case: A resort chain replaced conventional foam cores with proprietary Quick Dry Foam cores. Over two wet seasons:

- User complaints about damp seating dropped ~80 %

- Cushion replacement intervals extended ~25 %

- Daily maintenance burden declined materially

Marine & Yacht Seating

In marine settings, exposure to salt spray, humidity, and cyclical wet conditions is constant. Quick Dry Foam enables drainage rather than trapping water, reducing corrosion risk on embedded metal supports. Many marine-grade variants also incorporate hydrophobic or salt-resistant treatments.

Outdoor Bedding / Camping Equipment

Portable systems like glamping beds, foldable cots, or outdoor lounge pads benefit from a Quick Dry Foam core (protected by a shell). The foam’s drainage capability, lightweight nature, and structural support make it ideal for modular outdoor applications.

Design Guidelines & Selection Criteria

Key Metrics & Target Ranges

Below is a sample specification table for a robust foam grade:

| Metric | Significance | Typical Target / Benchmark |

|---|---|---|

| Open porosity | Ensures free fluid/air pathways | ≥ 90 % void |

| Density | Structural stability, sag resistance | 2.5–3.5 lb/ft³ (≈ 40–56 kg/m³) |

| Air permeability (CFM) | Evaporative convection support | ≥ 15–20 CFM (per ASTM standards) |

| Compression set/sag | Durability under load | ≤ 20 % after 72 h at 50 % deflection |

| Rebound / elasticity | Shape recovery & comfort | ≥ 95 % rebound |

| UV / thermal aging | Outdoor environmental resistance | ≥ 2000 h accelerated UV exposure |

| Antimicrobial / mold resistance | Biological stability | ASTM G21 “no growth” rating |

These benchmarks provide a baseline for procurement and quality assessment.

Structural & Flow Layout Approaches

- Design vertical drainage channels aligned with gravity

- Use gradient pore architecture (larger lower pores, finer upper pores)

- Reinforce high-stress zones (edges, corners) with thicker struts

- Add a thin comfort layer or fiber wrap without blocking airflow

- Align cushion shell drainage ports/grommets with internal channels

Procurement & Quality Control Recommendations

- Request third-party lab test reports for porosity, airflow, aging, and compression

- Perform wet–dry cycling tests (soak → drain → dry over many cycles)

- Examine microstructure (pore uniformity, strut integrity) via microscopy

- Monitor batch-to-batch consistency in density, porosity

- Define maintenance protocols (rinse, dry, rotate) in product documentation

Performance Testing & Comparative Insights

Drying Curve Comparison

A simplified schematic:

In lab data from Urecel, Quick Dry Foam retains ~40 % of water after 60 seconds vs ~80 % for conventional foam; by 3 hours, moisture is nearly gone, whereas conventional foam still holds substantial water. (Urecel Quickdry)

Cyclic Load & Deformation Tests

When subjected to extended compression cycles (e.g., 100,000 cycles), a well-engineered Quick Dry Foam may retain ≥ 90 % of original thickness and elasticity, outperforming lesser reticulated materials prone to creep and sag.

Environmental Aging Profiles

Using accelerated aging (UV, temperature cycling, humidity) simulates extended field exposure. Tracking shifts in modulus, strut cracking, and moisture absorption provides insights into long-term stability. For open-structure foams, moisture ingress is known to impact viscoelastic behavior over months. (arXiv)

Advantages, Constraints & Future Directions

Key Advantages

- Rapid moisture evacuation reduces mold/mildew risk

- Extended service life in high-humidity or wet climates

- Lower maintenance burden in hospitality/resort settings

- Hygienic performance under heavy use

Constraints & Challenges

- Higher material/processing cost

- Possible firm handfeel if not engineered carefully

- Longevity is vulnerable if stabilizers or protective layers are inadequate

- Lower insulation capability in cold or temperate climates

Future Trends & Innovation Paths

- Bio-derived / sustainable foam blends (e.g., algae-based matrices)

- Adaptive porosity or smart foam structures

- Hybrid composites combining a drainage core + insulating zones

- Recyclable/circular foam systems to reduce environmental impact

Conclusion (with Happy Rattan’s Insight + Keyword Use)

Through this analysis, high-density Quick Dry Foam emerges as a strategic material choice in demanding outdoor and marine contexts by reconciling the rapid drying imperative with structural and comfort demands. When properly engineered, it offers superior drainage, durability, lower maintenance overhead, and enhanced user experience.

From a leading industry perspective, Happy Rattan underscores that function must not compromise comfort:

“We reject any foam described as ‘quick-dry’ unless it passes multi-season soak-dry cycling while retaining compression resilience and seat comfort,” states a design engineering guideline within Happy Rattan’s material sourcing policy (internal assertion).

Accordingly, Happy Rattan mandates full transparency of performance data — porosity, compression set, aging behavior — and typically favors layered constructions (thin comfort face over Quick Dry Foam core) to maximize both performance and user satisfaction.

For B2B product engineers, procurement professionals, and material specifiers, the path forward is clear:

- Prioritize validated performance over marketing claims.

- Insist on comprehensive test data (porosity, airflow, soak/dry cycles, aging).

- Design composite foam systems to marry drainage and comfort.

- Communicate the dual value proposition — “rapid drainage + long-term comfort” — in product specs and client materials.

By adopting high-density Quick Dry Foam under rigorous engineering and quality control regimes, your organization can deliver durable, high-performance outdoor seating solutions that differentiate in longevity, user experience, and maintenance efficiency.

FAQ — High-Density Quick Dry Foam in Outdoor Applications

Q1: What exactly is “Quick Dry Foam” and how is it different from regular foam?

A: Quick Dry Foam is a reticulated polyurethane foam engineered by removing most cell walls to create an open-strut network that allows water to flow through freely. Unlike conventional closed-cell or standard PU foam, which traps moisture, Quick Dry Foam enables rapid drainage and airflow. (LQ International)

Q2: How quickly can high-density Quick Dry Foam dry after being soaked?

A: Under moderate outdoor conditions, a well-designed high-density Quick Dry Foam can reduce residual moisture to negligible levels within 3 to 6 hours, whereas conventional foam may still retain significant water even after 24 hours. (CG OUTDOOR FURNITURE)

Q3: Will using Quick Dry Foam make my cushions feel too firm or uncomfortable?

A: Not necessarily. Quality Quick Dry Foam systems often adopt layered or composite structures: a soft face or fiber wrap layer over a drainage core ensures cushioning softness while the core handles water flow and structural support. (LQ International)

Q4: In what scenarios is high-density Quick Dry Foam most beneficial?

A: It excels in environments with moisture exposure, humidity, or rainfall cycles. Typical scenarios include resort outdoor furniture, marine seating, poolside lounges, and camping cushions. In these settings, fast drying reduces mold risk, shortens downtime, and extends cushion life. (eastar-group.com)

Q5: What technical specifications or test reports should I request when sourcing Quick Dry Foam?

A: Ask suppliers for verifiable data, including:

- Open porosity / void fraction (≥ 90 %)

- Density, rebound/elasticity/compression set

- Air permeability (e.g., CFM or Darcy)

- Accelerated UV / aging / hydrolytic stability reports

- Antimicrobial / mold resistance tests (e.g., ASTM G21)

- Cyclic soak-dry durability test results