Introduction:

If you buy once and buy right, outdoor furniture should survive sun, salt, spills, and seasons. In 2025, the best outdoor furniture material isn’t a one-word answer-it’s the right base material + finish class + lab-verified performance for your climate, use case, and budget.

What “best” means in 2025: five decision pillars

- Climate exposure – UV intensity, rainfall, humidity, and especially chlorides in coastal wind/spray.

- Application – Hospitality pool vs. rooftop bar vs. streetscape: very different abuse and cleaning chemistry.

- Finish & testing – Powder coat class (AAMA/FGIA 2604 vs 2605), plus corrosion and UV/weathering tests.

- Sustainability & compliance – FSC for hardwoods; documented recycled content for plastics; relevant industry guidance.

- TCO – 10-year cost including refinish cycles, labor, downtime, and replacements.

Helpful standards and primers: AAMA/FGIA 2605 (store overview), FGIA technical resources, ASTM B117 salt spray (example copy), ASTM G154 overview (Q-Lab), ISO 4892-2 overview (ISO), BIFMA OF-2025 Outdoor Furniture Whitepaper (PDF), FSC Chain-of-Custody, Chlorides & stainless steel (ASSDA).

Quick scorecard: best material by climate & application

| Scenario | Recommended “Best” Stack | Why it wins | Risk if under-spec’d |

|---|---|---|---|

| High UV / desert sun | HDPE poly lumber with HALS + UV testing to ASTM G154 or ISO 4892-2 | Color-through and low maintenance; proven UV resistance when stabilized and tested | Fading/embrittlement without UV stabilization/testing |

| Coastal / salt spray | 316 stainless hardware/frames or powder-coated aluminum to AAMA/FGIA 2605 + sealed welds + ASTM B117 reference | 316’s molybdenum improves pitting resistance; 2605 retains color/gloss longer | Tea staining, pitting, and coating undercutting in 1-3 seasons |

| Four-season freeze-thaw | Powder-coated aluminum (2604/2605) or HDPE; avoid moisture-wicking fibers | Coatings/plastics shrug off wet/dry cycles; fewer checks | Peeling finishes, checks in softwoods |

| Hospitality pool deck | Resin (PE) wicker over aluminum, or HDPE, with 316 fasteners; slip-safe feet | Light, cleanable, chlorine-tolerant | Broken weaves, rusted screws |

| Public realm / heavy use | 6063-T5/T6 aluminum or 316 stainless; robust wall thickness; security fasteners | Structural robustness + corrosion resistance | Bent frames, early corrosion, theft |

Why these standards: AAMA/FGIA 2604/2605 classify architectural powder-coat performance; ASTM B117 screens chloride-driven corrosion; ASTM G154 and ISO 4892-2 screen UV/weathering on plastics/coatings. [For more information, please read: Patio Furniture Powder Coating vs. Sprays]

Deep dives by material (what to specify & what to avoid)

Powder-coated aluminum (6063-T5/T6)

Why choose it: Light, corrosion-resistant, and extrudable into ergonomic profiles. The finish class matters as much as the metal. Specify AAMA/FGIA 2604 for solid mid-term color/gloss retention, or 2605 for premium longevity (especially for harsh UV/coastal). Helpful explainers: Gordon, Inc. AAMA 2604/2605 paper (PDF), AAMA 2604 vs 2605 (AMICO).

RFQ snippet (copy-paste):

- Alloy 6063-T5/T6; minimum wall thickness to suit span/loads.

- Pretreatment compatible with marine/coastal use; TGIC-free polyester powder.

- Powder coat to AAMA/FGIA 2604 (good) or 2605 (best). Attach third-party test report or applicator certification (e.g., PCI 4000 / AAMA 2604/2605 compliance example).

- Seal all welds; no raw aluminum exposed in hollow sections.

Field note: In sun-blasted rooftops or boardwalks, 2605’s superior color/gloss retention reduces repaint cycles versus 2604 (better TCO).

Stainless steel (304 vs 316)

When 316 wins: Anywhere with airborne chlorides or de-icing salts. The molybdenum in 316 increases pitting resistance; 304 often tea-stains or pits at the coast. See: ASSDA: Chlorine vs. Chloride and ASSDA FAQ on general corrosion (PDF).

RFQ snippet:

- Grade 316 for coastal installs; brushed/electropolished finish to reduce crevice traps.

- Isolate dissimilar metals; specify 316 fasteners throughout (including hidden).

- Cleaning plan included in O&M (frequency rises with salt load).

Budget tip: 316 costs more up front but reduces stain remediation and replacements-often winning on 3-5-year TCO in coastal sites.

Teak and other hardwoods

Why teak endures: Dense grain and natural oils resist rot and insects; it weathers to a silver patina. For responsible sourcing and proof of claims, require FSC Chain-of-Custody on invoices and packing lists.

RFQ snippet:

- FSC-certified Tectona grandis; moisture content 10-12% at assembly.

- Mortise-and-tenon joinery; stainless fasteners; breathable covers.

- Maintenance: gentle wash; optional seasonal oiling if you want to keep the golden hue.

When to avoid: In high-turnover hospitality where seasonal wood care is unrealistic; choose HDPE or 2605 aluminum instead.

HDPE “poly lumber”

What it is: High-density polyethylene, often with recycled content. Premium brands use color-through lumber and HALS UV stabilization. See: POLYWOOD FAQs (HDPE + UV inhibitors), scientific background on HALS: 3V Sigma-HALS protecting plastics.

RFQ snippet:

- Color-through HDPE with declared recycled content; request UV stabilization documentation and ASTM G154/ISO 4892-2 exposure data (ΔE*, gloss retention, impact).

- Stainless fasteners; robust section thickness to control creep.

- Provide a cleaning chemical compatibility statement.

Why buyers like it: Minimal maintenance and long warranties; ideal for high-UV decks and education/parks where abuse is common.

“All-weather wicker” (resin) on aluminum frames

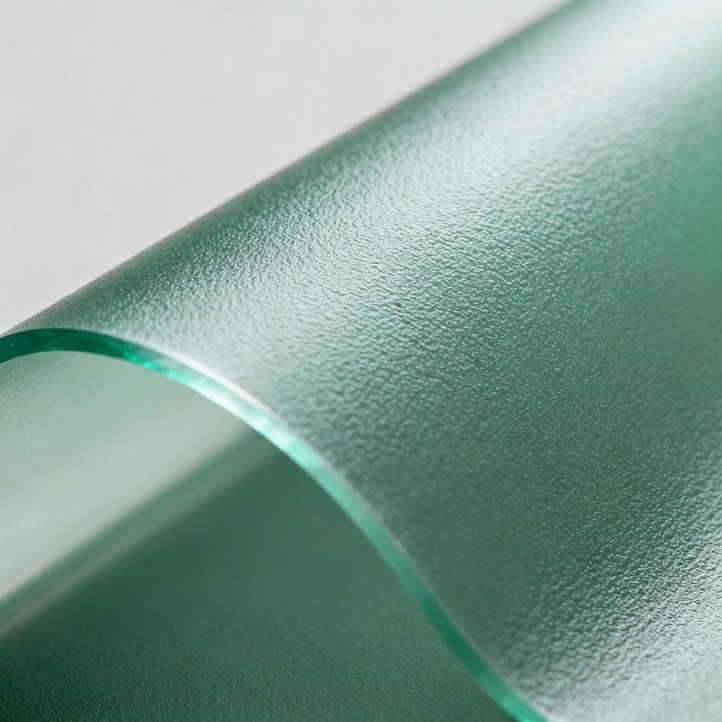

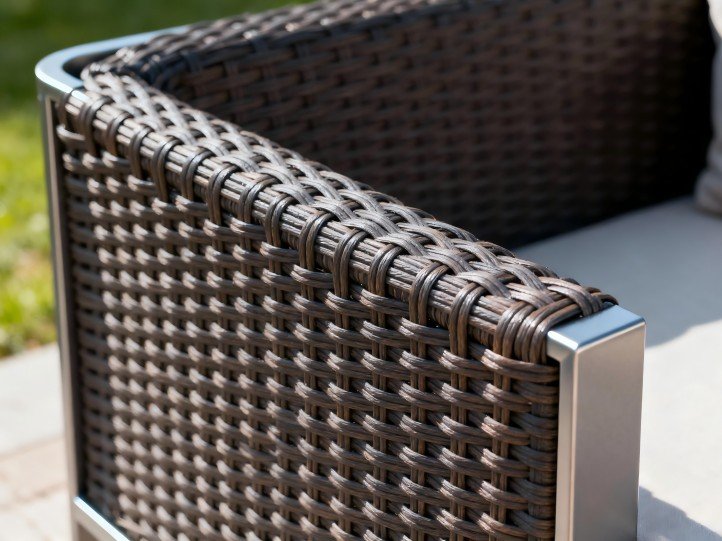

What it really means: “Wicker” is a weave method. Outdoor-safe “all-weather wicker” is typically polyethylene (PE) resin strands, UV-stabilized and woven over a powder-coated aluminum frame. Avoid PVC weaves for long, hot UV exposure when possible. Primer: HDPE vs. PVC wicker (buyer explainer).

RFQ snippet:

- UV-stabilized PE wicker with color-through pigment; welded aluminum frame (2604/2605 finish).

- 316 fasteners in coastal installs; replaceable glides.

- Specify weave density (g/m or strands/cm) for consistency; chlorine-splash tolerance for pool deck applications.

Finishes & tests that actually predict lifespan

Powder-coat class (AAMA/FGIA 2604 vs 2605)

- 2604: Solid performance; typical mid-market choice for inland or moderate UV.

- 2605: Premium color/gloss retention and corrosion resistance-recommended for intense UV or coastal installs. Learn more: AAMA 2605 overview, plus practical explainers from industry (AMICO guide, Colorific primer).

Corrosion screening: ASTM B117 (salt fog)

Use ASTM B117 to compare coating systems and pretreatments under chloride load. It doesn’t replicate all field conditions but is a consistent screening tool for scribe creep, blistering, and undercutting.

UV/weathering for plastics & coatings: ASTM G154 vs ISO 4892-2

- ASTM G154 – fluorescent UV/condensation cycles; excellent for plastics/coatings screening.

- ISO 4892-2 – xenon-arc exposure; broader solar spectrum simulation. A quick lab explainer: Q-Lab on QUV vs. Q-Sun (PDF).

Show your stakeholders: short videos – ASTM G154 UV weathering demo or another lab demonstration.

Sustainability & compliance signals specifiers trust

- Hardwoods: Require FSC Chain-of-Custody documentation (certificate number + transaction IDs).

- Plastics: Ask for recycled content declarations and UV-stabilizer disclosure; link to third-party test summaries for ASTM G154/ISO 4892-2.

- Industry guidance (2025): The BIFMA OF-2025 Outdoor Furniture Whitepaper frames safety/performance for exterior commercial furniture and references relevant testing. See also the BIFMA Standards FAQ page.

10-year TCO model (illustrative)

| Material Stack | Capex Index (Year 0) | Annual Care (hrs/set) | Refinish Cycle | Likely 10-yr Events | TCO Notes |

|---|---|---|---|---|---|

| HDPE + 316 fasteners | 1.0 | 1-2 | None | Hardware swap rare | Low labor; heavy pieces deter theft. For UV assurance, ask for ASTM G154/ISO 4892-2 data. |

| Alu 6063 + 2604 | 0.9 | 3-4 | 5-7 yrs repaint (some sites) | Touch-up chips | Good inland value; upgrade to 2605 for harsh UV. |

| Alu 6063 + 2605 | 1.1 | 2-3 | 8-10 yrs repaint (harsh UV) | Minimal fading | Best for UV/coastal; see AAMA 2605. |

| 316 stainless brushed | 1.3 | 3 | None | Tea-stain cleaning only | Coastal winner; fewer replacements; see ASSDA chloride guidance. |

| FSC Teak | 1.2 | 4-6 | Oil/clean annually | Surface checks possible | Highest perceived luxury; requires a maintenance culture; verify FSC CoC. |

Assumptions: Hotel pool deck with daily use; coastal multipliers increase corrosion risk (justify 316 or 2605). Standards references underpin durability expectations, but local cleaning practice still drives outcomes.

Implementation playbook: from shortlist to signed PO

Climate & site audit (add to drawings)

- Distance to ocean, predominant winds, salt film risk, UV index, shade hours.

- Chemicals in play (chlorine, sunscreen, cleaning products).

- Cleaning access (water, storage), anchoring constraints, and theft risk.

Material & finish requirements (paste into RFQ)

- Frames: Aluminum 6063-T5 (min wall X mm) with TGIC-free polyester powder coat complying with AAMA/FGIA 2605 (2604 acceptable inland). Include pretreatment for coastal.

- Hardware: All visible and concealed fasteners 316 stainless; isolate dissimilar metals; supply material certificates. See ASSDA guidance.

- Plastics: HDPE with color-through pigment and HALS; provide ASTM G154 or ISO 4892-2 exposure results (ΔE, gloss, impact retention). Reference Q-Lab primer.*

- Wood: FSC-certified teak; attach FSC Chain-of-Custody certificate and transaction IDs.

Test documentation to submit

- Corrosion: ASTM B117 hours to first scribe creep/blister; coating DFT and adhesion notes.

- UV/weathering: ASTM G154 or ISO 4892-2 exposure with ΔE*, gloss retention, and impact results.

Warranty & maintenance

- Written cleaning SOP; finish warranty terms aligned to coating class (longer for 2605).

- Confirm spare parts support and lead times.

Conclusion: So…what’s the best outdoor furniture material in 2025?

- Coastal: 316 stainless or aluminum finished to AAMA/FGIA 2605, plus disciplined 316 fasteners and cleaning.

- High-UV inland: HDPE poly lumber or aluminum with 2605; verify ASTM G154/ISO 4892-2 performance.

- Luxury hospitality: FSC teak where maintenance culture exists; otherwise, aluminum/HDPE for operational simplicity.

In short, the best outdoor furniture material is the one whose base + finish class + test evidence match your climate and workload-and are written, verified, and warranted in your PO.

FAQ

Q1. What is the best outdoor furniture material for coastal areas?

A: If you’re within a few kilometers of the ocean or get salt-spray winds, spec 316 stainless or aluminum with AAMA/FGIA 2605 powder coat-and ensure all fasteners are 316 as well. This pairing resists chloride-driven pitting and finish undercutting better than 304 or lower-class coatings. For background, see ASSDA on chlorides.

Q2. Is AAMA/FGIA 2605 worth the premium over 2604?

A: Yes-in harsh UV or coastal installs. 2605 is engineered for superior color/gloss retention and corrosion resistance over longer exposures than 2604, which can reduce repaint cycles and downtime. See practical comparisons: AMICO guide.

Q3. Does HDPE “poly lumber” fade in strong sun?

A: Quality HDPE with HALS UV stabilizers and verified ASTM G154/ISO 4892-2 data resists fading and embrittlement far better than unstabilized plastics. Brand example: POLYWOOD’s UV-inhibiting ColorStay™.

Q4. Is teak still worth it in 2025?

A: For premium projects with a maintenance plan, FSC-certified teak offers longevity and a high-end aesthetic (silver patina). For low-maintenance operations, consider HDPE or aluminum finished to 2605. Verify sustainability via FSC Chain-of-Custody. Q5. Which tests should I require in my RFQ? At minimum: ASTM B117 (corrosion) for metals/coatings and ASTM G154 or ISO 4892-2 (UV/weathering) for plastics/coatings. Tie acceptance to outcomes (ΔE*, gloss retention, scribe creep).