Introduction: Why fade costs you more than color

Outdoor furniture works under relentless UV, heat, moisture, and pollutants. If the finish or polymer isn’t protected, surfaces chalk, yellow, and drift in color (ΔE) long before the product’s design life-driving warranty exposure, rework, and brand inconsistency across resorts, HOAs, and retail fleets. The most controllable lever to extend appearance life is the right UV Stabilizers package, validated by standards-based testing such as ISO 4892-3 for plastics and ISO 16474-3 for coatings, commonly run on a QUV fluorescent UV tester. See the overviews at ISO 4892-3 (Q-Lab explainer), ISO 16474-3 abstract, ASTM G154 practice (PDF), and QUV equipment page.

[For more information, please read: Outdoor Furniture Materials Guide]

Photodegradation 101: the science behind fading

What UV does to materials. UV photons trigger free-radical reactions in polymers and resin binders, causing chain scission and crosslinking. The results you see (and customers complain about) are gloss loss, chalking, embrittlement, and measurable color shift (ΔE). Field severity depends on latitude, altitude, season, and shade. For a shared language with non-technical stakeholders, point them to the public-health version of intensity: the WHO UV Index explainer. A higher UVI correlates with faster material damage, not just sunburn risk. Bottom line: higher UVI markets (Phoenix, AZ, Miami, FL, coastal/tropical resorts, high-altitude ski towns) demand stronger stabilization and outdoor-rated pigments.

What UV Stabilizers do (and don’t)

Three workhorse categories

- UV Absorbers (UVA). These molecules filter incoming UV and convert it to harmless heat before it reaches pigments or the polymer backbone. Common families include benzotriazoles and benzophenones; examples: Tinuvin® 326 datasheet (PDF) and Tinuvin® 312 product page.

- HALS (Hindered Amine Light Stabilizers). HALS don’t absorb UV; they scavenge free radicals formed by UV attack, operating through a regenerative nitroxyl cycle that keeps working over time, especially valuable in pigmented/thicker sections. See BASF Light Stabilizers overview.

- Quenchers/Nickel chelates (niche today). Historically used to deactivate excited states in certain systems, but modern UVA+HALS packages largely dominate.

Synergy beats solo. In most outdoor furniture systems, UVA + HALS blends outperform single-additive strategies. BASF’s portfolio pages illustrate the roles of each class for plastics and coatings: Tinuvin® for plastics (portfolio) and Tinuvin® light stabilizers for coatings. Limits and misconceptions. UV Stabilizers cannot turn a low-lightfast pigment into an outdoor pigment, nor can they fix under-cured coatings or poor dispersion. Think of stabilizers as a seatbelt-essential, but not the whole safety system.

The anti-fading stack: beyond additives

Pigment strategy

In general, inorganic pigments (e.g., iron oxides, ultramarines) offer better lightfastness and weatherability than many organic chemistries, making them reliable for earth tones and architectural neutrals. For bright chromatic reds/yellows/oranges, select outdoor-rated grades and pair them with higher UVA loads. For context, see primers like Inorganic pigments & durability summary (Nature topic) and practical iron oxide guides (e.g., iron oxide properties & uses).

Resin and geometry

Polymer sensitivity differs: PP typically requires more stabilization than HDPE; thin sections, high-texture surfaces, and light colors weather faster. Basic mechanisms and mitigation are outlined in the BASF light stabilizers overview.

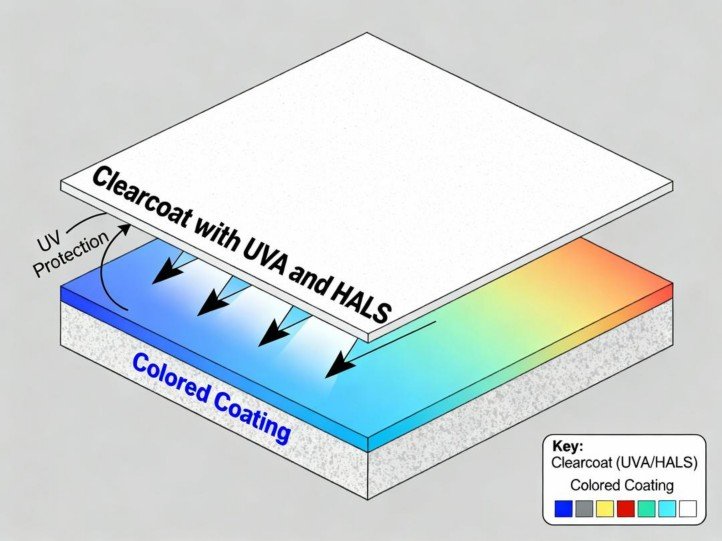

Coatings and clearcoats

For metal frames or wood-plastic composites, a clearcoat with UVA + HALS can dramatically improve color and gloss retention. See Tinuvin® light stabilizers for coatings and the broader BASF coatings light-stabilizer landing page.

How to specify UV Stabilizers for outdoor furniture (B2B playbook)

Use these non-proprietary ranges as starting points. Confirm with your additive supplier and run lab trials.

| Substrate / Finish | Typical UV Stabilizer Approach | Starting Range (wt% on resin/binder) | Notes |

|---|---|---|---|

| HDPE lumber (extruded) | HALS + UVA package | HALS 0.15-0.30; UVA 0.10-0.30 | Dark colors may allow lower UVA; brights need higher UVA. |

| PP injection (chairs, tables) | High-efficiency HALS (incl. NOR-HALS) + UVA | HALS 0.20-0.50; UVA 0.20-0.50 | PP is more UV-sensitive; NOR-HALS options like Tinuvin® XT 200 FF can help. |

| PU clearcoat (on metal/wood) | Benzotriazole UVA + HALS blend | 1.0-2.0 total (on binder) | Aim for ≥40-50 μm film build. Consider packages like Tinuvin® PUR 866. |

| Powder coating (polyester/TGIC) | UVA + HALS for coatings | 0.8-1.5 total (on resin) | Outdoor-rated pigments are essential; extra HALS reduces chalking. |

| PVC straps/weave | HALS + UVA + compatible heat stabilizer | HALS 0.20-0.50; UVA 0.20-0.40 | Verify compatibility with Ca-Zn/organotin systems. |

Testing that predicts outdoor reality (embed in drawings & POs)

Don’t accept “UV resistant” as a claim-specify conditions.

- Plastics: call out ISO 4892-3 (fluorescent UV) and specify the lamp type (e.g., UVA-340), irradiance setpoint (e.g., 0.89 W/m² @ 340 nm), black panel temperature, cycle (UV/condensation), and total exposure hours. See ISO 4892-3 test standard (Q-Lab explainer).

- Coatings: reference ISO 16474-3 (fluorescent UV for paints/varnishes). See the ISO 16474-3 abstract.

- US practice: ASTM G154 is widely used for fluorescent UV exposures; note it’s a practice that must be paired with exposure/evaluation details. See ASTM G154 practice (PDF) or the ASTM store page.

- Equipment shorthand: call out “Q-Lab QUV or equivalent” to improve reproducibility and communication with labs; see the QUV product page and the QUV education page/video.

Video resources for teams (optional)

KPI & acceptance criteria you can copy-paste

- Color shift: ΔE*(2000) ≤ 3.0-4.0 after 1000 h ISO 4892-3 UVA-340 (tighten or relax by color; reds/yellows are stricter).

- Gloss retention: ≥ 70% at 60° after 1000 h.

- Chalking: ≤ Rating 1 per ASTM D4214 Method A (for coatings).

- Visual: No cracking, brittleness, or fiber-print.

- Documentation: Supplier COA showing additive type/level; lab report with lamp, irradiance, cycle, BPT, and ΔE/gloss/chalking data. These benchmarks align with common industry expectations and the mechanisms summarized in BASF’s light-stabilizer overview.

Field performance & evidence (what “good” looks like)

A brand shipping HDPE Adirondack chairs into high-UVI markets (Phoenix, AZ, Miami, FL) switched from UVA-only to a UVA + HALS package and upgraded to outdoor-rated pigments for bright reds/yellows. After validating 1000 h of ISO 4892-3 (UVA-340; 8 h UV @ 60 °C / 4 h condensation @ 50 °C), the team saw ΔE* reductions of ~40-60% in pilot placements and a significant drop in color-related complaints year-over-year. This tracks with the Environmental Effects Assessment Panel’s findings that solar UV materially decreases polymer durability; see the UNEP EEAP 2023 update (PDF) and the NOAA-hosted assessment summary. (Plug in your own measured values; the magnitude varies by resin, color, and geometry.)

Procurement checklist (use in RFPs)

- Resin & geometry: What resin, wall thickness, and texture? Are pigments outdoor-rated?

- Additive package: Which UV Stabilizers-UVA, HALS, or both? Are HALS high-MW / NOR-HALS (see Tinuvin® XT 200 FF)?

- Dosage & dispersion: Target wt-% and masterbatch carrier; processing stability.

- Compatibility: Interactions with heat stabilizers, FRs, biocides, or anti-drips?

- Testing: Which ISO 4892-3 / ISO 16474-3 cycles, UVA-340, irradiance setpoint, hours, and acceptance limits (ΔE, gloss, chalking)? Provide “QUV or equivalent” for clarity (see QUV equipment page).

- Documentation: COA, TDS/SDS, and accelerated-weathering report.

Practical selection table: match your use case

| Use Case | Environment | Preferred Package | Why / Notes |

|---|---|---|---|

| Resort pool loungers (PP) | High UVI + chlorinated water | NOR-HALS + benzotriazole UVA | PP sensitivity plus bright brand colors; HALS manages radicals, UVA shields pigments. See Tinuvin® XT 200 FF and Tinuvin® 326. |

| Coastal café seating (polyester powder coat) | UV + salt air | UVA + HALS in topcoat | Better gloss/color retention; HALS limits chalking. See BASF coatings stabilizers. |

| HDPE Adirondack (deep colors) | High sun; visible fade risk lower | HALS-leaning package with some UVA | Matrix protection dominates; dark shades mask ΔE but still degrade. See BASF plastics light stabilizers. |

| Boutique umbrellas (PU clear over fabric) | High UV + moisture | High-load UVA + HALS | Clearcoat must filter UV before it reaches dyes/fibers. See Tinuvin® PUR 866. |

Implementation tips (QA/production)

- Masterbatch first. For molded plastics, prefer a masterbatch route for dispersion and dosing control; verify carrier compatibility with your resin.

- Color control. Use ΔE*(2000) with a practical acceptance band by color family (e.g., mid-tones ≤3.0, vibrant reds/yellows ≤2.0-2.5).

- Film build and matte/gloss. In coatings, target sufficient film build; matte textures tend to look faded earlier due to scattering-budget extra UVA/HALS.

- Maintenance narrative. Provide care instructions so clients understand UV’s effect.

Conclusion: “Color that lasts” starts with the right UV Stabilizers

For outdoor furniture brands, appearance is life. Pair UV Stabilizers (UVA + HALS) with outdoor-rated pigments and standards-based verification (ISO 4892-3, ISO 16474-3, ASTM G154 on a QUV) to create a repeatable, spec-driven anti-fading program. Lock these requirements into drawings and purchase orders now-next season’s reviews, returns, and margins will thank you. Quick references: ISO 4892-3 explainer, ISO 16474-3 abstract, ASTM G154 PDF, QUV equipment, BASF Tinuvin® for plastics & for coatings.

FAQ (snippet-friendly, user-style questions)

Q1: Do UV Stabilizers stop fading completely?

A: No-they slow it significantly. Best practice is a UVA + HALS package, outdoor-rated pigments, and verification with ISO 4892-3 / ISO 16474-3 or ASTM G154 on a QUV tester. See ISO 4892-3 explainer, ISO 16474-3 abstract, ASTM G154 PDF, and QUV equipment.

Q2: How many lab hours equal one year outside?

A: There’s no universal conversion. Use accelerated tests (e.g., ISO 4892-3 UVA-340 cycles) to compare formulas and set ΔE/gloss targets, then confirm with limited field exposure. See ISO 4892-3 explainer.

Q3: Which is better, UVA or HALS?

A: They do different jobs. UVA filters harmful wavelengths; HALS neutralizes the radicals created by UV. Most outdoor furniture needs a blend. See BASF overview of light stabilizers and Tinuvin® for coatings.

Q4: Do darker colors need less protection?

A: Dark shades hide color change better, but the polymer still degrades. Keep HALS at robust levels for structural integrity; adjust UVA based on pigment sensitivity. See BASF plastics light stabilizers.

Q5: What should my spec say to suppliers?

A: Call out UV Stabilizers (UVA + HALS), target dosages, pigment grade requirements, and acceptance limits (e.g., ΔE* ≤ 3-4 at 1000 h, gloss ≥70%) under ISO 4892-3 / ISO 16474-3 or ASTM G154 on a QUV. Pointers: ISO 4892-3 explainer, ISO 16474-3 abstract, ASTM G154 PDF, QUV equipment.