Introduction

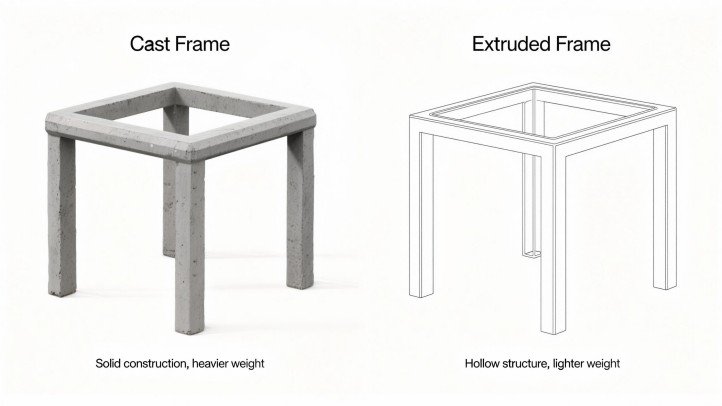

Selecting the right outdoor furniture frame isn’t just a materials decision—it sets the tone for aesthetics, warranty risk, corrosion performance, logistics, and long-term maintenance. In commercial and hospitality programs, frame construction usually boils down to two proven aluminum routes: cast aluminum and extruded aluminum. Each offers real strengths and real trade-offs in geometry, tolerances, finishing behavior, cost structure, and serviceability.

Fast answer:

- Choose Cast for sculpted, one-piece forms and premium, tactile surfaces.

- Choose Extruded for long spans, low weight, tight tolerances, and replaceable parts at scale.

[Read more: Aluminum powder coating guide] • [Read more: Why High End Cast Aluminum Patio Furniture Delivers Unmatched Durability and ROI] • [Read more: Choosing 6063-T5 vs 6061-T6 for frames]

60-second decision matrix (for busy project managers)

| Priority | Pick First | Why | When to consider the other route |

|---|---|---|---|

| Sculpted, organic shapes | Cast | One-piece, freeform geometry with soft edges | Add extruded rails for long straight members |

| Tight tolerances & modularity | Extruded | Dimensional repeatability; integrated slots/ribs | Cast nodes for complex junctions |

| Lightweight for shipping/install | Extruded | Better strength-to-weight on long spans | Cast accents where hands/eyes focus |

| Premium touch & hidden welds | Cast | Fewer joints; luxurious curvature | Extruded sub-frames for structure |

| Coastal/harsh UV finish spec | Either | Finish class matters more (AAMA/FGIA 2604/2605) | See the finishing section below. |

How each process works (and why it matters outdoors)

Cast aluminum frames (often A356 Al-Si-Mg): molten metal is poured or injected into a mold, then heat-treated (commonly T6). The big win is geometry freedom—rounded arms, sculpted legs, and “one-piece” junctions that can eliminate multiple welds. Engineering caution: porosity management is key (gas/shrinkage pores), which impacts finishing if not controlled.

Extruded aluminum frames (commonly 6063 in T5/T6): a billet is pushed through a die to form continuous profiles, then cut, machined, and joined. You can design features into the profile itself—channels for concealed fasteners, ribs for stiffness, wire chases, and drip edges. AEC design resources cover alloy selection, tolerances, and die choices in depth.

Why outdoor furniture cares: casting unlocks sculpted, hand-friendly forms; extrusion delivers long, straight members with consistent fit-up and lower weight—ideal for benches, loungers, and installation teams working to a schedule.

Mechanical performance (typical ranges—design to supplier certs)

| Alloy & Temper | Process | Typical Yield (MPa) | Typical Tensile (MPa) | Notes |

|---|---|---|---|---|

| 6063-T5 | Extruded | ~110–160 | ~150–205 | Excellent extrudability & weldability; furniture-friendly. |

| 6063-T6 | Extruded | ~160–240 | ~205–250+ | Higher strength after aging; mind post-weld softening. |

| A356-T6 | Cast | ~140–230 | ~200–310 | Properties depend on process quality & heat-treat. |

Design takeaways

- For long spans / weight-sensitive seating, 6063 extrusions offer strong strength-to-weight and predictable section properties.

- For organic shapes & one-piece nodes, A356-T6 castings can meet furniture loads with proper wall thickness and ribbing—quality control is everything. (Paradigm)

- Welding & HAZ: MIG/TIG on 6xxx in T-tempers can reduce local strength due to precipitation changes; parameter control minimizes HAZ softening. Similar cautions apply to cast A356 near welds. (SpringerLink)

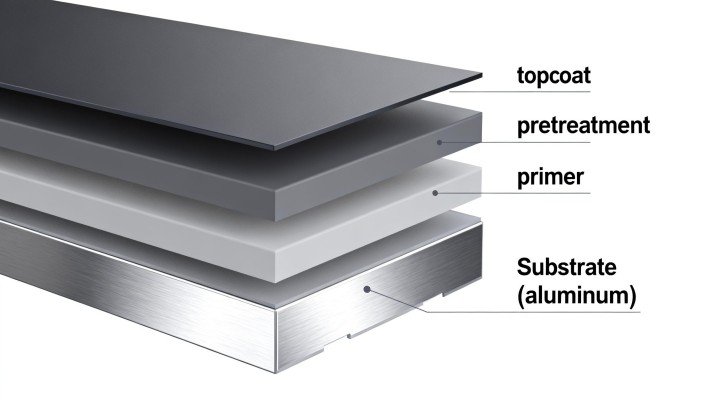

Corrosion & finishing: matching the coating to the environment

For exterior furniture, the finishing choice is as important as the substrate.

- AAMA/FGIA 2604 (high-performance powder/polymer) vs AAMA/FGIA 2605 (superior performance, often PVDF-based) are the industry’s workhorse specifications for architectural aluminum. Use 2605 for the harshest UV/salt exposure; 2604 serves many inland projects. Reference these in RFQs and warranties.

- Comparative corrosion testing: ASTM B117 (neutral salt spray) remains a common accelerated, comparative screen for pretreatments/coatings. It does not represent real-world weathering but is helpful for line checks and supplier benchmarking. (ASTM International | ASTM)

- Cast-specific watch-outs (powder coating): porosity can outgas during cure, causing pinholes/craters. Mitigate with rigorous pretreatment, pre-bake (de-gassing), optimized cure windows, and outgassing-forgiving (OGF) powders or primers. (Powder Coated Tough)

- Anodizing: 6063 extrusions anodize to crisp, uniform finishes. Al-Si castings often anodize grey/patchy because silicon alters oxide appearance; powder/PVDF is usually safer for cast surfaces where appearance matters. If you must anodize cast parts, manage expectations and process tightly.

Dimensional control, assembly, and maintainability

- Extruded frames offer tight, repeatable tolerances along the length that reduce shimming and speed assembly. Integrated features (T-slots, tabs, drip edges) improve serviceability—replace a damaged rail without scrapping the entire unit. (Alexandria Industries)

- Cast frames shine where you want soft, sculpted edges and complex junctions that would require multiple fabricated parts. Machine critical datums after casting to hit alignment in assembly.

- Hybrid strategy (common in hospitality): cast nodes for the look and touch points; extruded rails for structure and replaceable parts.

Compliance & documentation (protecting your warranty)

Ask suppliers to include a simple acceptance pack per lot:

- Alloy/temper certs (e.g., 6063-T5 / A356-T6),

- Coating conformance to AAMA/FGIA 2604/2605 (or AAMA 611 for anodized),

- Pretreatment & cure records,

- ASTM B117 (or equivalent comparative test) results + adhesion/film thickness,

- Agreed on visual criteria and rework thresholds.

Sustainability notes your ESG team will like

Using recycled (secondary) aluminum typically saves about 95% of the energy versus primary production—one reason many brands write recycled content into specs. Request recycled content declarations and EPDs where available.

Cost, lead time, and TCO (what the CFO will ask)

- Tooling: Extrusion dies are relatively fast and low-cost for simple profiles; casting molds cost more but can collapse multi-piece weldments into fewer parts—sometimes saving downstream labor. AEC resources outline die design and cost drivers.

- Lead time: After die approval, extrusions often run quickly. Casting lead-times vary with foundry loading and mold complexity.

- TCO: For distributed rollouts, extruded systems with standardized joints reduce freight weight, installation time, and spare-part costs. Cast wins when premium aesthetics and one-piece sculptural junctions are the value driver.

Welding & joints (keep the structure honest)

- 6063 extrusions weld well (MIG/TIG). Use appropriate filler (ER4043/ER5356 families), manage heat input, and plan for some HAZ softening in precipitation-hardened 6xxx tempers.

- A356 cast nodes can be welded; control porosity and watch over-aging of T6 near the weld. Many programs minimize cosmetic welds on visible cast faces or switch to mechanical fastening at those interfaces.

Recommended route by scenario

- Luxury resort seating with sculpted arms/legs: Cast primary forms; machine seating interfaces; finish to AAMA/FGIA 2605 in strong UV/coastal zones.

- Municipal benches & transit seating: Extruded rails/legs for serviceability; powder to AAMA/FGIA 2604; specify vandal-resistant fasteners and replaceable parts.

- Pools, marinas, coastal decks: Start from the finish spec (2605 preferred or a proven 2604 system) and design for drainage/crevice control. Favor extruded structure; use cast accents selectively. Validate pretreatment and film builds with comparative testing (e.g., B117). (ASTM International | ASTM)

- Franchise rollouts on tight timelines: Extruded kit-of-parts with snap-fit or hidden fasteners; keep die complexity modest for speed.

Expert insight (coatings engineer, editorial note):

“Near salt or high UV, start at the finish class and work backward. If your warranty uses 2605 language, demand test panels run through the same line and cure window as production—not just brochure panels.” (Based on FGIA/AAMA practice.)

Comparison table you can reuse

| Criterion | Cast A356-T6 | Extruded 6063-T5/T6 |

|---|---|---|

| Design freedom | Sculpted, organic; one-piece nodes | Long, straight members; built-in features |

| Weight | Heavier at equal stiffness | Strong strength-to-weight on spans |

| Tolerances | Machined datums after casting | Tight, repeatable along length |

| Coating behavior | Manage outgassing; pre-bake/OGF | Friendly to powder & anodize |

| Welds | Often, fewer (one-piece) repairs are trickier | Straightforward MIG/TIG; manage HAZ |

| Tooling | Higher mold cost, premium forms | Lower die cost, fast iteration |

| Best fit | Premium sculpted collections | Scalable, modular rollouts |

Quality checklist from drawing to sign-off

- Alloy & temper called out (e.g., 6063-T5 for rails; A356-T6 for nodes).

- Coating spec and color system (AAMA/FGIA 2604 or 2605; gloss & color tolerances defined).

- Pretreatment, film build, and cure windows documented.

- Salt-spray (ASTM B117) or equivalent comparative testing defined with visual criteria (blistering, creep from scribe).

- Fastener isolation plan (nylon/EPDM pads) in coastal installs.

- Service parts: stocked extruded rails; cast replacements made-to-order.

Conclusion—Put environment → structure → finish in that order

For most commercial programs, design from the outside in: environment (UV & salt → finish class & pretreatment) → structure (spans, weight, modularity → cast vs. extruded mix) → finish (appearance, touch, brand color). If you need sculpted, single-piece elegance, go Cast. If you need light, modular, and repeatable frames, go Extruded. Many best-in-class outdoor furniture frame systems combine both: cast nodes where hands linger and eyes focus, extruded rails where strength-to-weight and serviceability rule.

FAQs (optimized for “People Also Ask”)

Q1: For a coastal resort, is a cast or extruded frame more durable?

A: Durability hinges more on the finish spec than the forming route. In harsh UV/salt environments, specify AAMA/FGIA 2605 (or a proven 2604 system with robust pretreatment), verify with comparative corrosion testing (e.g., ASTM B117), and design for drainage/crevice control. Use extruded members for long spans and add cast accents where needed.

Q2: Can I anodize cast aluminum frames to match anodized extrusions?

A: You can, but Al-Si castings often anodize to a darker/patchy gray compared with 6063 extrusions. For a premium appearance on cast parts, powder or PVDF is safer; reserve anodizing for extruded components unless the look is acceptable.

Q3: Why do cast parts sometimes show pinholes after powder coating?

A: Porosity can outgas during cure, creating pinholes/craters. Mitigate with pre-bake (de-gassing), careful cure windows, and OGF powders or primers; validate with production-line test panels. (Powder Coated Tough)

Q4: Which is stronger for frames—6063-T6 or A356-T6?

A: Both can exceed 200 MPa in tensile strength, but geometry and quality dominate performance. Design to supplier-certified values and consider HAZ softening near welds.

Q5: What documents should I require from vendors at delivery?

A: Alloy/temper certs, coating conformance to AAMA/FGIA 2604/2605 (or AAMA 611 for anodized), pretreatment & cure records, and comparative corrosion results (ASTM B117) with agreed visual criteria.