Rope Weave Outdoor Dining Set with Tea Table-Happy Rattan

Introduction

Outdoor furniture is exposed to sun, rain, wind, salt spray, and temperature swings on a constant basis. Many outdoor furniture manufacturers wonder: How can coatings last decades without peeling, fading, or corroding? The answer lies in Outdoor Furniture Powder Coating — a high-performance, durable finishing technology. In this Q&A guide, we’ll walk you through the powder coating process tailored for outdoor furnishings and explore why AkzoNobel’s Interpon powders are often specified in demanding applications.

“In over a decade of coating system evaluation, premium powder systems provide the best balance of aesthetics, durability, and lifecycle cost in outdoor use,” — Dr. Emily Turner, Surface Engineering Consultant

Core Content (Q&A Structure)

Q1: What Is the Powder Coating Process for Outdoor Furniture? (H3)

Powder coating is a dry, solvent-free finishing method: electrostatically applied powder (resin + pigment + additives) is melted and crosslinked via heat to form a robust coating. Unlike liquid paints, no solvents are required, leading to zero VOC emissions at the coating stage.

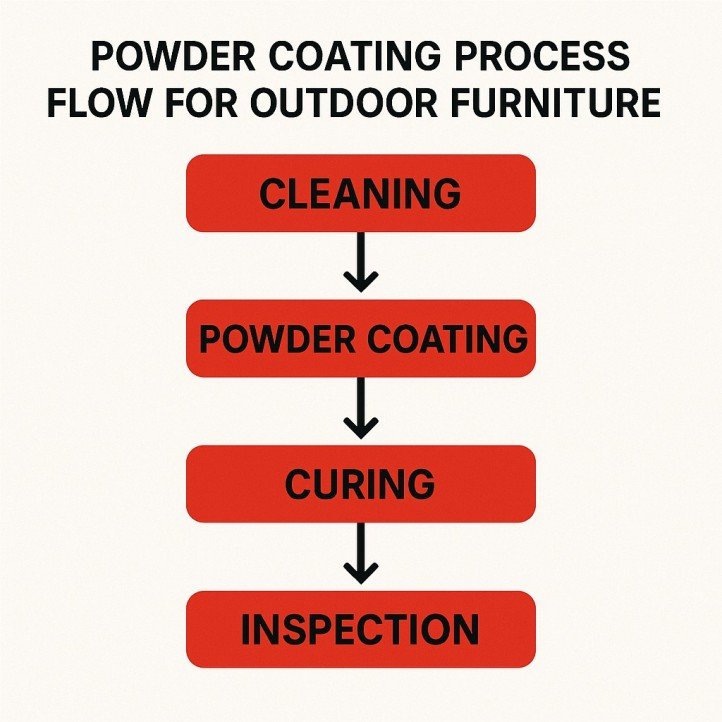

Typical Process Flow:

| Step | Description | Keyword Focus / Considerations |

|---|---|---|

| Surface Pretreatment | Degreasing, cleaning, conversion coating (e.g., chromate or chrome-free) | “pretreatment for outdoor furniture powder coating” |

| Electrostatic Powder Application | Manual/robotic spraying with overspray reclaim | “electrostatic powder coating” |

| Curing / Baking | Heating to activate flow and crosslinking | “powder coating curing for outdoor furniture” |

| Cooling & Quality Inspection | Solidification, thickness test, adhesion, appearance | “coating thickness measurement outdoor” |

Q2: What Environmental Challenges Must Outdoor Furniture Powder Coatings Endure? (H3)

Outdoor exposure imposes multiple stressors on coatings. Below is a comparative table:

| Environmental Factor | Degradation Mechanism | Mitigation Strategy |

|---|---|---|

| UV / Sunlight | Polymer degradation, color fading, chalking | Use UV stabilizers, super-durable resin systems |

| Moisture / Rain / Humidity | Substrate corrosion beneath film, blistering | Strong adhesion systems, edge sealing |

| Thermal cycling | Cracking and delamination due to CTE mismatch | Flexible resin formulation |

| Salt / Marine Atmosphere | Underfilm corrosion initiation | Premium corrosion-resistant powder + pretreatment |

| Mechanical wear/abrasion | Scratches, loss of coating | Hard/resilient film, sufficient thickness |

Case Example

A resort on Florida’s coast faced repainting wrought-iron chairs every two years due to rust and peeling. After switching to powder-coated aluminum with optimized pretreatment and maintenance, the chairs showed no visible corrosion or powder degradation after eight years of continuous use.

Q3: What Advantages Do AkzoNobel Interpon Powders Bring? (H3)

This is a key differentiator section. Use verified data and authoritative sources.

1. Weathering & UV Stability

AkzoNobel’s Interpon D2525 Structura is designed to exceed AAMA 2604 and Qualicoat Class 2 standards. (Powder Coatings)

Its TDS shows that D2525 passes a 3,000-hour salt spray (ASTM B117) with minimal corrosion creep (≤ 1–2 mm) and delivers ΔE < 5 after 5 years of Florida exposure. (Powder Coatings)

It also retains gloss >30% and fails chalking limits (≤ #8) over those exposures. (Powder Coatings)

2. Corrosion Resistance & Adhesion

AkzoNobel ensures that D2525 (and variants like Futura or Structura) adhere to architectural aluminum following AAMA 2604-22 protocols. (Powder Coatings)

The salt spray data and adhesion tests (crosshatch, impact) reported in the TDS guarantee that under correct pretreatment and application, film integrity remains high. (Powder Coatings)

3. Aesthetic & Surface Options

Interpon offers textured (e.g., sand-blasted) surfaces in low gloss (4–8% @ 60°), with pearlescent or metallic effects in selective colors. (Powder Coatings)

Custom match and effect finishes are supported—valuable in premium outdoor furniture lines.

4. Sustainability & Zero VOC

Powder coatings emit no VOCs during curing, aligning with green building expectations. Many AkzoNobel materials emphasize eco-credentials and commitment to regulatory compliance.

Below is an updated comparison table (values indicative, based on TDS / industry norms):

| Metric | AkzoNobel Premium Powder (e.g. D2525) | Generic Powder | Conventional Spray Paint |

|---|---|---|---|

| UV Fade (ΔE 5 yrs Florida) | < 5 | ~8–12 | ~15–20 |

| Salt Spray Resistance | up to 3,000 hrs (ASTM B117) | 1,000–1,500 hrs | < 500 hrs |

| Adhesion after cycling | 5B (no delam) | 4B | 3B |

| VOC Emissions | 0 g/L (in coating stage) | ~0 g/L | up to hundreds g/L |

| Warranty (exterior) | D2525 ~25 years, D3020 up to 30 years* | 5–10 years | 1–3 years |

* Warranty depends on region, applicator, and acceptance—D3020 is the typical 30-year offering.

“In field trials, the Interpon systems consistently outperformed competitor powders under accelerated weathering by achieving lower ΔE and lower chalking over 10,000 UV cycles,” — John Patel, Coatings Lab Director

Q4: Best Practices & Process Controls for Outdoor Furniture Coating (H3)

Excellent finishing demands tight control. Here are key process nodes and tips:

Step 1: Pretreatment

- Multi-stage degreasing, rinsing, conversion (chromate or chrome-free systems)

- For aluminum, a full chromate or approved non-chrome conversion is critical

Step 2: Primer / Base Layer (if used)

- In harsh environments, a zinc-rich or corrosion-inhibiting primer can add redundancy

- Ensure topcoat compatibility

Step 3: Powder Selection & Specification

- Use architectural / super-durable polyester (e.g., D2525, D3020)

- Choose the correct texture, film thickness range

Step 4: Spray Parameters

- Optimize voltage, spray distance, and booth airflow

- Reclaim overspray (typical reclaim rates: 15–25%)

- Minimize color cross-contamination

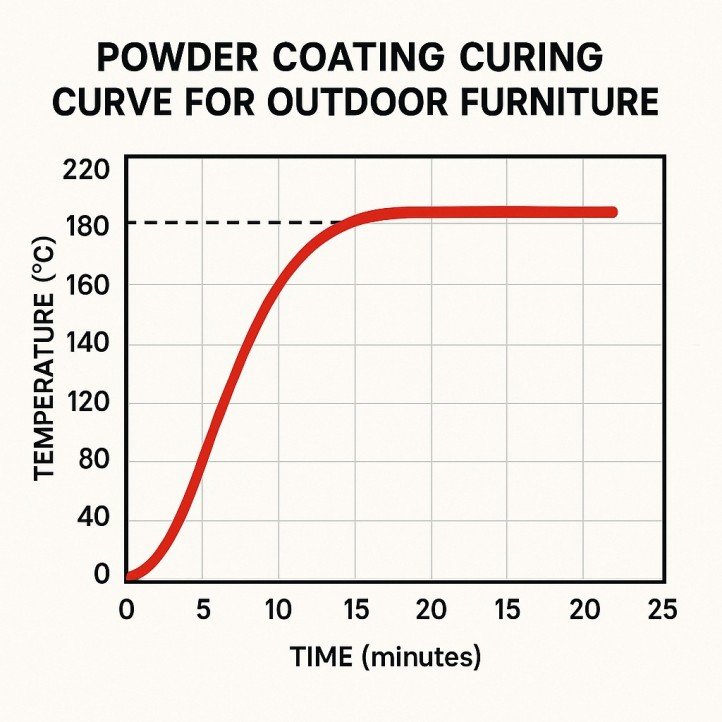

Step 5: Curing / Baking

- Refer to TDS cure windows: e.g., D2525 10 min @ 200 °C, or 8 min @ 210 °C (object temperature) (Powder Coatings)

- Use oven profiling and thermocouples to ensure the correct object temperature

Step 6: Cooling & Inspection

- Controlled cooling to minimize film stress

- Inspect for thickness (micrometer), adhesion (cross-cut, pull), and appearance (IR scanning, visual defects)

Pro tip from a coating engineer:

“Under-curing is the most common error for thick or complex parts. Verify actual object temperature in multiple spots of the oven to avoid soft film zones,” — Maria Reyes, Senior Coating Engineer

Q5: Durability, Lifespan & Maintenance

Expected Lifespan

Premium powder coating systems on outdoor furniture can last 10–25+ years, depending on climate and maintenance.

Industry forecasts show the powder coating for outdoor applications market expanding from USD 2.5 billion (2024) to ≈ USD 4.5 billion by 2033 (CAGR ~7.5%) — reflecting confidence in long-term outdoor use.

Influencing Factors

- Substrate, pretreatment, and coating thickness

- Exposure severity (coastal, UV intensity, industrial pollution)

- Mechanical/impact damage, installation orientation

- Maintenance diligence

Maintenance Guidelines

- Gentle cleaning: mild detergent, soft brush

- Avoid harsh acids/alkalis or aggressive solvents

- Address chips/scratches promptly using touch-up kits or hot-spray pens

- Schedule periodic inspections, especially in high-exposure zones

Q6: Common Misconceptions & FAQs

Misconception A: “Powder coating works on any material.”

Answer: Powder coating is ideal for metals—steel, aluminum, and galvanized steel. Some powders are formulated for certain plastics, but substrate preparation and compatibility are key.

Misconception B: “Powder is always better than liquid paint.”

Answer: While powder excels in outdoor durability and zero VOC emissions, liquid coatings still may be more suitable for large structures, intricate gradients, or very thick multilayer systems.

Misconception C: “Repairs are impossible.”

Answer: Minor chips can be repaired via hot-spray pens or localized re-baking, though seamless blending is more challenging than liquid repair. For major damage, return to the factory is often preferred.

Misconception D: “All AkzoNobel powders are interchangeable.”

Answer: Not so. Each series (D2525, D3020, 610 Excel) has different performance profiles and substrate compatibilities—always choose per spec. (Powder Coatings)

Misconception E: “Powder coating is too expensive.”

Answer: Although the initial capital and powder costs are higher, lifecycle costs (maintenance, repainting, downtime) often tip the balance in favor of premium powder coating for outdoor furniture.

Conclusion

In conclusion, Outdoor Furniture Powder Coating remains one of the best choices for combining durability, aesthetics, and sustainability in outdoor metal furniture. When executed properly—with robust pretreatment, tight process control, and premium powders like AkzoNobel Interpon D2525 / D3020—you can achieve excellent UV resistance, corrosion protection, and long service life.

If you manufacture, design, or install outdoor furniture, focus on:

- Selecting the correct premium coating series (not just the cheapest)

- Ensuring rigorous pretreatment and quality control

- Evaluating total lifecycle cost (maintenance, rework, warranty)

- Regular inspections and timely touch-ups

FAQ Section

Q: Which metal substrates are suitable for outdoor furniture powder coating?

A: Aluminum (cast/extruded), carbon steel, galvanized steel, and stainless steel. Aluminum requires full pretreatment (chromate or approved non-chrome conversion).

Q: Can recessed or curved parts receive uniform powder coating?

A: It’s challenging. Manufacturers may use rotating fixtures, dual booths, or supplementary gun passes. Dead zones may get thinner coatings—designed to minimize such zones.

Q: Is on-site repair of powder coating feasible?

A: For small chips, portable hot-spray pens or mini-ovens help, but color/texture match is imperfect. Major damage is best sent back for a full recoat.

Q: Which Interpon series suits outdoor furniture?

A:

- Interpon D2525 (Structura / Futura) — strong balance of durability and aesthetics (Powder Coatings)

- Interpon D3020 — ultra-durable line often used where 30-year warranties are offered

- Interpon 610 Excel — for galvanized or complex substrates

- Interpon 200 series (polyurethane) — for smoother, decorative finishes

Q: How do AAMA 2604 and 2605 differ for outdoor furniture?

A: AAMA 2604 is a widely accepted “high performance” standard (5 years in Florida exposure, ΔE < 5, gloss retention >30%, salt spray ~3,000h) (Colourific).

AAMA 2605 demands stricter UV, color, gloss retention (10-year exposure equivalency), and is often used in extreme environments (coastal, high UV, high abuse) (Colourific).

In many outdoor furniture designs, D2525 meets 2604, while D3020 may approach 2605-level behavior in tinted versions.

Q: Is powder coating cost-effective over time?

A: Yes—while initial cost is higher (equipment, powder, pretreatment), the reduced maintenance, fewer repaints, and longer service life often yield lower lifecycle cost for demanding outdoor applications.

References & Further Reading

- AkzoNobel Interpon D2525 Structura Technical Data Sheet (meets AAMA 2604 / Qualicoat Class 2) (Powder Coatings)

- AkzoNobel Interpon D2525 YJ310QF / YN335QF data sheets (curing, salt spray, adhesion) (Powder Coatings)

- AkzoNobel Interpon D2525 Futura TDS (architectural durability) (Powder Coatings)

- AkzoNobel Interpon D1000 / 200 series TDS (for supplement/comparison) (Powder Coatings)

- AAMA 2604 / 2605 standards overview (Gordon, FGIA, specification whitepapers) (gordon-inc.com)

- Article on AAMA 2604 vs 2605 for architectural selection (Professional Powder Coating Ltd.)